Formulators are constantly updating their adhesive and sealant formulations; consequently, manufacturers of the equipment used to measure the adhesives’ and sealants’ flow behavior properties must keep current with these new formulations. Flow characteristics can vary dramatically, both during processing and in final application by the end user, due to the range of raw materials and rheology additives needed for a diverse range of applications. Viscometers and rheometers are the instruments of choice used to measure flow behavior, providing critical data such as yield stress, flow curve vs. shear rate, viscosity vs. temperature profile, creep behavior, and recovery.

Terminology

The shear rate is the rate at which the sample is sheared or “worked,” and depends both upon the geometry of the application tool and the rate of the deformation applied to the material. Non-Newtonian materials are those whose viscosity changes as a function of shear rate; thus, we refer to the apparent viscosity at a particular shear rate. “Shear-thinning” or “pseudoplastic” materials are those whose apparent viscosity decreases with increasing shear rate.

Rheology can be simply defined as the study of flow. Various instruments can be used to analyze rheological behavior, including a controlled stress rheometer that is equipped with a vane geometry spindle. The vane geometry is convenient when testing highly heterogeneous materials or samples that “channel.” A simple test for channeling is to stick a pencil straight down into the material and then remove it straight up and out. If this leaves a hole that doesn’t readily fill back in, then the vane spindle may be appropriate for making the viscosity test.

Joint Compound

Joint compound is used when working with gypsum board, as well as for patching, filling and finishing. It is designed to keep various solid fillers suspended while the material is at rest and to be applied smoothly with a trowel or spatula. Therefore, its viscosity is very high at low shear rates (e.g., at rest), but significantly lower when troweled or being spread—corresponding to higher shear rates.

Joint compound was tested in its tub at room temperature. Figure 1 shows the highly shear-thinning behavior. The test was performed in controlled shear stress mode, in which the applied stress was increased over 100 sec. Software available for use with controlled stress rheometers allows for test automation and data capture/storage in a lab PC. Taking multiple data points over a range of shear stress values or shear rates allows operators to more completely understand the compound’s behavior. This also provides more information to formulators who may better tailor the product for field use.

All-Purpose Glue

An all-purpose glue has apparent viscosities significantly lower than those of the joint compound; thus, the glue can be readily squeezed out of a bottle and onto a selected area. These glues are widely used with numerous materials.

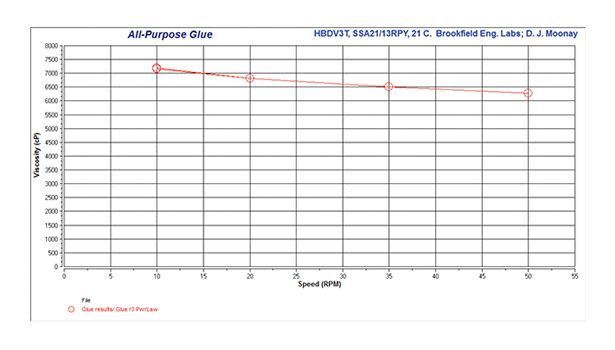

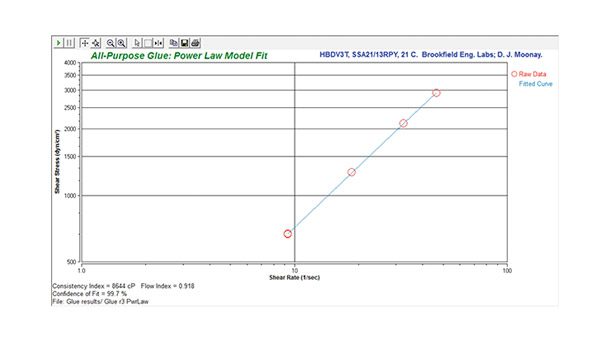

Approximately 10 mL was tested in a coaxial/concentric cylinder geometry, using a small sample adapter accessory on a standard benchtop rheometer. The speed ramp from 5 to 50 rpm and then back down to 5 rpm was programmed in standalone mode via the touchscreen interface. The Power Law math model was selected to fit the data as a reporting step at the end of the speed ramp. The Power Law math model is often fit to rheological data sets to provide parameters used in designing process equipment. The data was graphed in real time during the test; this was followed automatically by the Power Law graph. Data was saved in the rheometer’s internal memory, and the files were subsequently saved onto a flash drive, copied to a PC, and imported into software for further analysis. This software was used to create and save printable graphs in both .jpg and .bmp formats.

The results of a multi-speed test at room temperature are shown in Figure 2. The material exhibits shear-thinning behavior. The Power Law math model fit to the above data is shown in Figure 3. The calculated Consistency index, 8644 cP, is a measure of the material’s viscosity at low shear rates. The Flow index of 0.918 is less than 1, indicating shear-thinning behavior. At 99.7%, the confidence of fit indicates a very good fit of this model to the data.

Although the data in these experiments was obtained at room temperature, baths or other accessories may be used if specified temperatures are needed. In addition, real-time data display and subsequent math model fitting may be done on the rheometer in standalone mode should the user wish to use the instrument on the production floor for QC. One advantage when using software with a PC is that it can simultaneously control the instrument and a programmable temperature bath, thereby automating the testing.

Ensuring Quality

A range of rheological equipment is available with a variety of spindle geometries to properly perform quality control analyses of various adhesives and sealants. Vane spindles are useful in testing heterogeneous, solids-filled compounds directly in the materials’ containers. Coaxial/concentric cylinder geometry allows testing of more homogeneous materials. Multi-speed tests are advantageous in showing a given sample’s behavior under different shearing conditions, potentially allowing better tailoring of a product’s flow behavior for its intended application.

For more information, contact the author at (508) 946-6200, ext. 7144, or d_moonay@brookfieldengineering.com; or visit www.brookfieldengineering.com.