The DONG Energy Solar Challenge is a highly competitive solar boat race that generates some of the most dynamic designs and construction techniques in composite technology and sustainability. Thus, the event provided SCIGRIP Smarter Adhesives Solutions a platform to demonstrate the critical role that high-strength adhesives can play in bonding marine components.

Earlier this year, the adhesives manufacturer announced its sponsorship of the Polish team in The DONG Energy Solar Challenge. This bi-annual event, which takes place in Holland, attracts teams of composite engineers, boat builders, designers and technical students from all over the globe. Formerly known as the Green Solar Boat Team, the SCIGRIP Solar Boat Team offered technical advice and supplied a range of high-performance methyl methacrylate (MMA) structural adhesives during the boat’s prototyping phase and build process.

Adhesives in Boatbuilding

With manufacturing sites in the UK and U.S., SCIGRIP maintains a strong sales presence throughout Europe and North America. The company works with many leading marine customers.

“Huge opportunities exist for adhesive suppliers in the boatbuilding sector, as there is a strong interest to upgrade traditional and often time-consuming production methods with high-strength, reliable adhesive bonding processes,” said Mark Rogan, European Sales and Marketing manager.

MMAs are at the forefront of the structural adhesive evolution, addressing engineers’ needs for higher toughness and crack resistance under impact or fatigue with strengths exceeding most composite substrate’s inherent strength. MMAs also address assemblers’ needs for adhesion after minimal surface preparation, easy ratio-adjustable cure speeds to match the ambient temperature of the day, and good compatibility with lower surface energy engineering plastic substrates, such as ABS, PC or PMMA vacuum-formed sheets, which are sometimes used in conjunction with composite structures.

Specifically for boatbuilding, MMAs are available that:

• Provide long assembly time for complex jobs like bonding decks to hulls

• Provide primerless bonding to metals in applications that require they be attached to composites

• Resist UV, when white joints are exposed

• Can be accompanied by fire, smoke and toxicity certification, when needed for mass transport industries

Construction

With the SCIGRIP Solar Boat Team’s sights firmly set on winning the 2014 World Championship, they decided to design and build a new boat from scratch to enter the Challenge A class. This resulted in a hull that was even lighter than the team’s previous entry, which received the Innovation Award for the Lightest Boat in the Regatta in 2012. The engine features rare earth magnets, the strongest type of magnet available, thus increasing the efficiency of the drive system and boosting the vessel’s speed. Specialized software was also developed and used to optimize the boat’s energy and power consumption.

The solar boat was constructed at Cree Yacht Design in Poland. SCIGRIP supplied on-site technical support and a selection of high-performance, structural MMA adhesives. A two-component, high-viscosity MMA adhesive, SG230HV was used to bond large and demanding joints such as the bulkheads, engine column, and floater beam sections (see Figure 1). The product has a 10:1 mix ratio with adjustable cure rates ranging from 30 to 120 min.

“SCIGRIP’s adhesives were very straightforward and easy to work with,” said Skipper Bartosz Puchowski. “For the larger structural sections, we applied SG230HV, which offers a range of working times, is lightweight, easy to apply and exceedingly strong.”

For applications where substrates must bond and cure more rapidly, and where unprimed metals might be one of the components, SCIGRIP’s SG300-05 was applied in areas such as the perimeter of the electrical box. A black formulation of SG300 was also used to bond the deck to the hull, allowing the joint to blend seamlessly and be hidden from view. SG100 White was used to adhere the structure’s floats to the deck while also providing UV protection and resisting discoloration if the glue line is exposed.

“Gluing the bulkheads, engine column and deck-to-hull instead of laminating cuts the weight of the boat and dramatically speeds up the building process,” said Michal Wawrzyniak, composite technologist-constructor at Galeon and Repairman.

Marine Repair Packs

SCIGRIP provided customized marine repair kits to all race competitors. Each kit contained a selection of high-performance, fast-curing adhesives, as well as waterproof epoxy putty sticks to allow the teams to quickly mend any damages or breakage. These products have been specially formulated to bond easily with composite substrates, wood and a range of metals, making them flexible and suitable for a variety of applications.

Feedback from the competitors was positive, and several different repairs on competing boats were accomplished during the race. Team A07 Equipe Solar Brazil used a selection of SCIGRIP’s MMA and fast-curing epoxy adhesives to mend their propeller. Ordinarily, this type of damage would have required the complete lamination of the affected component with an epoxy resin—certainly not a procedure that can be conducted easily under wet race conditions. However, thanks to the products’ rapid cure times and ability to bond quickly with very little surface treatment, the team was able to complete the task swiftly and safely, enabling them to participate in the race the next day.

Race Results

The Solar Challenge 2014 proved a challenging and exhilarating week on the water. Some competitors performed consistently well and dominated the leaderboard, while others were forced to withdraw due to technical failure.

The SCIGRIP Solar Boat Team has competed in the DONG Energy Solar Challenge since its creation in 2005. The crew consists of a dedicated group of engineers with a vast knowledge of the marine industry, composites technology and the application of specialist adhesive products. This is combined with a passion for boats and environmental sustainability.

Since participating in the first Solar Challenge in 2005, they have been improving and enhancing the design of their boats to really push the boundaries in terms of performance and lightweight construction, achieving second place in 2008 and third in 2012.

This year, the SCIGRIP Solar Boat Team sailed very well and, despite slipping into third place on one occasion due to a navigational error, managed to lead their class for the duration of the week-long event. On July 5, they completed the course in the city of Leeuwarden ahead of their closest rivals by 4 min 18 sec, securing first place in the Challenge A class.

“Our team led the class on and off throughout the race,” said Bartosz Puchowski, captain and helmsman. “We sailed tactically and I am delighted our efforts paid off. The SCIGRIP

solar boat performed very well, and, thanks to its incredibly lightweight structure of 135 kg, it had a real speed advantage over our competitors during the reduced solar power phases of the race. As a result of this higher efficiency, the boat was then able to really excel during the longer, sunnier distances of the course, reaching maximum speeds of 24 km/hr.”

For more information, visit www.scigrip.com. Information about the DONG Energy Solar Challenge can be found at www.dongenergysolarchallenge.com.

About the Race

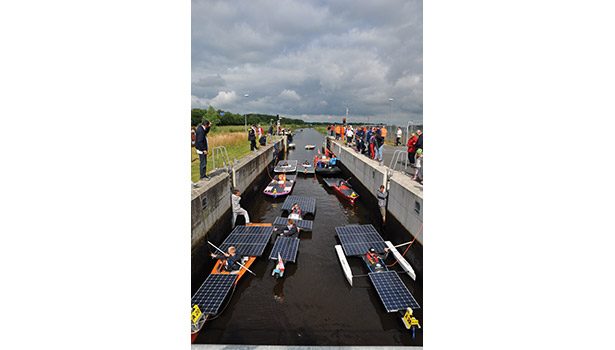

Hosted in Holland from June 28-July 5, the solar-powered contestis not confined to European entrants, but is a truly global gathering. This year’s competition included 40 international teams competing from countries such as Bahrain, China, the U.S., Brazil, Finland, Poland and Indonesia. Participants must complete the 250 km staged course in highly customized vessels powered only by energy from the sun and driven by solar panels.

The weeklong competition sees the teams navigate a challenging course across the north of The Netherlands between the cities of Blauwestad and Leeuwarden. Split into five different stages, contestants must participate in both sprint and endurance races, often exceeding distances of 50 km per day, making it a demanding and physical race.