Breaking Packaging Barriers with Oxygen Barrier Coatings

Oxygen barrier coatings can help to overcome the deficiencies of barrier technologies in packaging.

The packaging marketplace has a clear need for more functionality in barrier technologies that can provide varying degrees of preservation and protection for many substrates used in food and other packaging. Packaging products need to deliver enhanced shelf life, as well as sustainable, recyclable, metal-free and waste-reducing solutions. Traditional structures of glass, tin and foil are often seen as formidable barriers but, like all barrier technologies, have their disadvantages. Weight is considered a limiting factor for many of these substrates. A new approach replaces current barrier technology with printable barrier coatings.

While coated plastics offer barrier improvements, downsides include the generation of chlorine from polyvinylidene chloride (PVdC), the presence of metal in metalized film, the thickness of extruded laminates, and the fragile nature of aluminum oxide (AlOx)- and silicon oxide (SiOx)-coated films. New technologies such as nanocomposites can now be used to offset such deficiencies. In addition, these technologies can be formulated into functional coatings suitable for printing on packaging. Printers engaged in the oxygen barrier coatings market need options that are chlorine-free, enable lightweighting, improve sustainability and the ability to recycle, remove metal, are transparent, and offer an alternative to expensive barrier films.

The Value of Nanoparticles

Since the 1990s, nanoparticles have shown promise in coating formulations; most recently, they have shown exciting properties when made into oxygen barrier formulations. In packaging applications, they improve barriers to gases, aroma and UV light, among other features. Early problems with instabilities and poor coverage have been nearly eliminated with improved formulations and press techniques. Functional oxygen barriers of less than 0.06 cm3/100 in.2 over 24 hours at 23°C and 50% relative humidity on polyester are now routine.

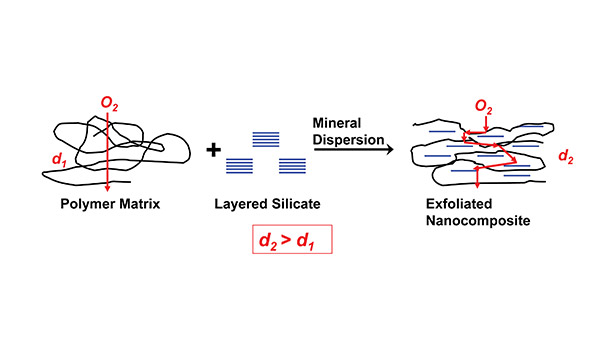

Nanoparticles are a finely dispersed (intercalated/exfoliated) silicate mineral in a polymer solution/dispersion. As the nanoparticles stack and arrange themselves on a flexible film substrate, they provide an obstacle to gases through the formation of a “tortuous path.” As shown in Figure 1, nanoparticles move from agglomerated clay to nanocomposite (exfoliated) coatings. As long as the distance d2 is greater than d1, a tortuous path exists and oxygen barrier performance is improved over an unmodified polymer matrix.

Understanding Oxygen Barrier Coatings

Oxygen barrier coatings are used in the packaging industry for both economic and performance reasons. The barrier performance of these nanocomposite materials is much improved over typical PVdC and ethylene vinyl alcohol (EVOH) barrier resins typically used in packaging films. While most commercial activity today is in the area of dry foods, prototypes have been made for liquid packaging and chilled packaging as well. Application methods have varied widely, with gravure, flexo and roller coatings all being successful.

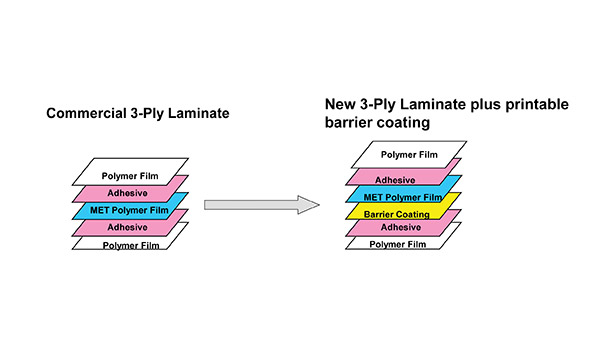

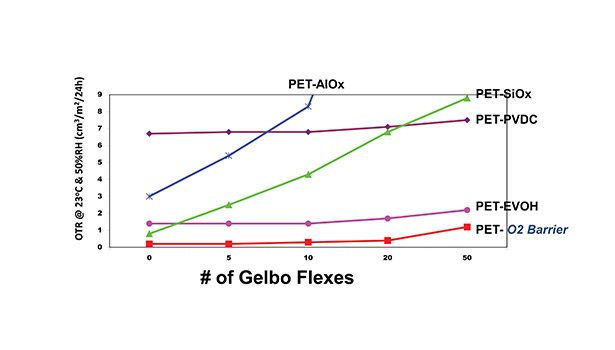

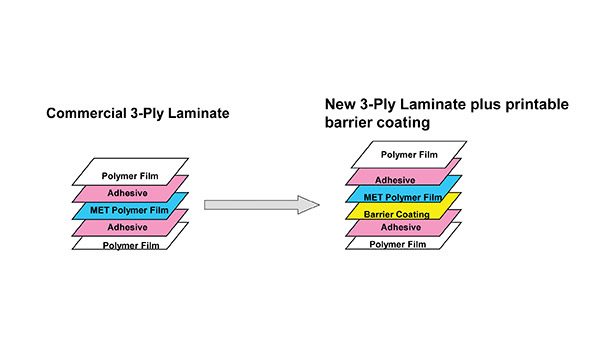

In a typical example, a familiar three-ply laminate composed of PET/mPET/PE can be replaced with a barrier-coated PET/PE structure. In addition to the obvious reduction of the one film layer, economic benefits result from using less adhesive and improving the visibility of the product. Barrier coatings of this type also offer an advantage in flex cracking, as they often are more flexible than mPET and oxide-treated films. In fact, the flex cracking improvement can be dramatic. In Figure 2, various coatings on typical packaging films show they were subjected to a Gelbo flex tester to measure oxygen barrier before and after flexing.

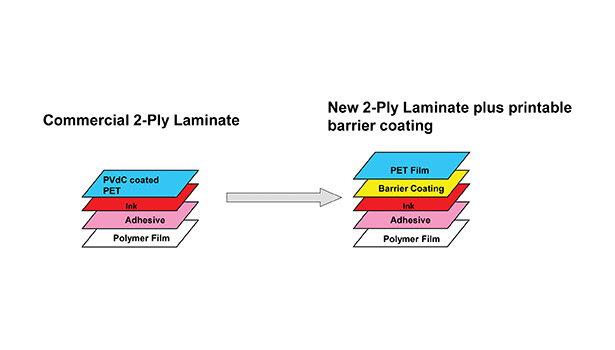

Another common example involves moving from commercial two-ply laminate to a new two-ply laminate plus printable barrier coating. In Figure 3, a coated film, PVdC-coated PET, is replaced with a barrier-coated corona-treated PET. The film is then laminated in the usual way to a sealant web of polyethylene. The benefits of this new structure are an improved oxygen barrier of up to 10 times the previous structure without chlorine and longer shelf life.

Figure 4 shows an example of oxygen barrier enhancement of a commercial three-ply laminate to a new three-ply laminate plus printable barrier coating. The barrier provided a lower cost advantage over alternative high-performance barriers.

Oxygen barrier coatings have recently been expanded to oriented polypropylene (OPP) and biodegradable films, and can also be crosslinked. These types of coatings also work well with solventless, 100% solids and solid-based adhesives. They have even been tested successfully with water-based adhesives on a limited basis. Barrier adhesives that use these properties are also in development.

Printable barrier coatings are now in testing for press speeds of 800-1,000 ft/min to accommodate the increasing need for coatings to dry faster when printed in-line on high-speed presses. However, most success with barrier coatings has been in off-line applications to maximize the color options on a print run.

Practical Concerns

Application weight of barrier coatings is critical to obtaining high barrier numbers. Depending on the substrate, application weights need to be adjusted to attain the barriers desired. In Figure 5, the relationship between application weight and oxygen performance is detailed.

Anilox and gravure suppliers can offer advice on the best screen and line combinations for the desired deposition weights. The nanoclay coatings are often supplied in two or more parts that need to be mixed together before use. An air-powered mixer press-side is usually adequate to mix the components before use.

Newer versions are available as a one-part system and should be kept from freezing. Films should be corona treated before coating, as it will enhance adhesion and improve lamination bond strength. Substrates should be free of dirt and dust as much as possible and should be applied as the first down with inks and other materials applied as a second down.

Multiple Benefits

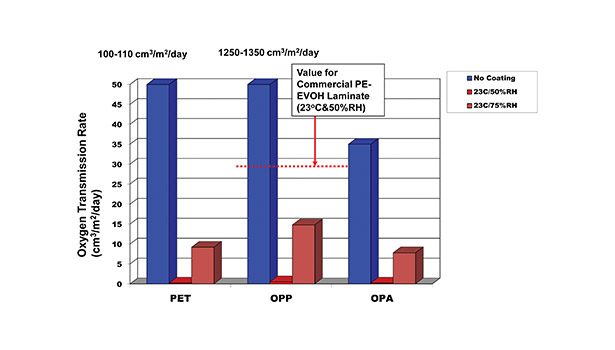

The oxygen transmission rates of typical flexible packaging materials can be drastically improved by printed oxygen barrier coatings and provide a viable alternative to existing film options. Figure 6 provides gas barrier performance across multiple substrates on polyester, oriented polypropylene and OPA at room temperature and relative humidity.

The nanocomposite coatings provide excellent barrier performance on both PET and OPP, with dry film weights as low as 0.2 g/m2 (dry). Gas barrier coatings also provide improvements in flexibility and lamination integrity. Benefits of oxygen barrier coatings include: excellent oxygen and aroma barrier, the replacement of PVdC and EVOH coatings, improved flex crack resistance of oxide/metallized films, and extended shelf life.

For additional information, contact the author at (973) 404-6288 or robert.oboyle@sunchemical.com, or visit www.sunchemical.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!