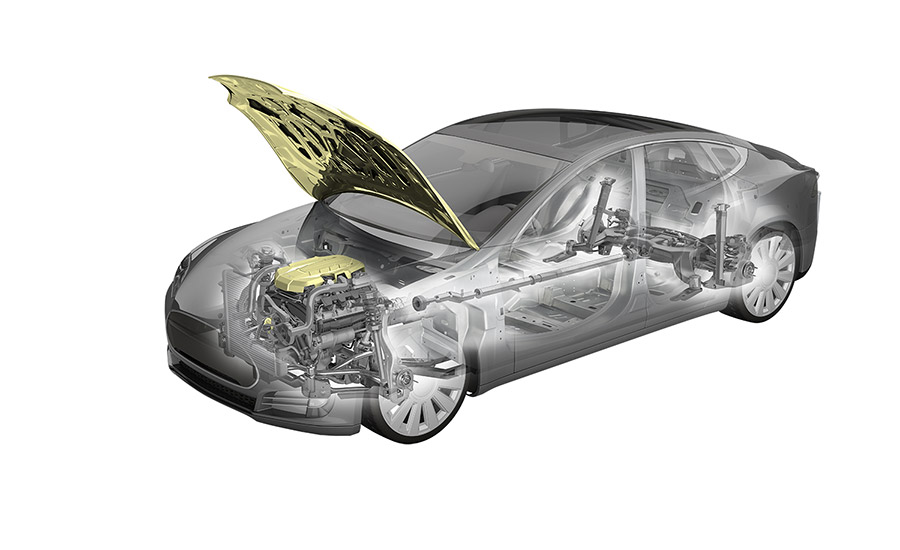

New SPECFLEX™ polyurethane systems from this company can be customized to meet under-the-hood performance requirements while balancing weight and processing targets. In addition to offering sound absorption, barrier and/or damping qualities for hoodliners, the systems can provide customized flammability and fast-curing systems to enable increased productivity and deliver large, complex shapes.

“SPECFLEX hoodliners enable customers to address global requirements for road traffic noise reduction,“ said Esther Quintanilla, Ph.D. EMEA marketing manager. “This lightweight polyurethane foam provides better acoustics control and weight advantages while also delivering a high level of thermoforming and stiffness. SPECFLEX can also be used for air intakes, engine side dashboards, transmission tunnel insulators and water boxes.”

The new SPECFLEX solutions are available with low density to pass requirements such as MVSS 302 and superior flammability to pass PV 3357. The foams meet physical, acoustical and processing requirements with minimal waste.

For more information, visit www.dowautomotive.com.