Home » automation

Articles Tagged with ''automation''

The five trends that are shaping the post-COVID-19 future include infection prevention, remote commerce, improving resiliency, greater agility, and macroeconomic impacts.

Read More

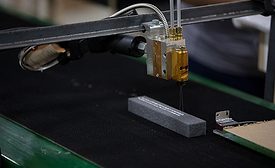

DISPENSE WORKS INC.: Bottle Filling and Robotic Assembly Dispensing System

An embedded dual memory processor with CF card reportedly requires no PC for operation and provides all preprogrammed software functions for filling, assembly, positioning, etc.

June 11, 2020

Case Study

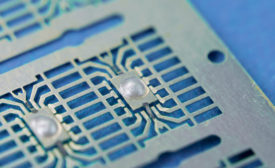

Benefits of Potting Electronics in a Vacuum

Vacuum potting is mainly aimed at electronic components with small openings and complex internal structures.

June 10, 2020

Case Study

Leveraging Adhesive Technology to Support Healthcare Workers

Chicago Glue recently helped Systematics more than double its output of face shields for healthcare workers on the front lines of the coronavirus pandemic.

May 22, 2020

MASTER BOND: Electrically Conductive Die-Attach Epoxy

EP17HTS-DA reportedly meets NASA low outgassing specifications, and its service temperature extends from -80 to 550°F.

May 5, 2020

DOW: Solventless Silicone Conformal Coating

Dow’s new environmentally responsible silicone technology reportedly promotes sustainability, health, and safety while reducing processing costs through automated spraying and fast, energy-efficient UV curing.

April 21, 2020

Real-Time Monitoring of Adhesive and Sealant Properties

The correct adjustment of flow characteristics of sealants and thermosetting adhesives is crucial to their performance in automated, high-speed production environments.

April 14, 2020

Understanding Net Weight Filler Configuration and Performance

Gravimetric or net weight fillers have replaced other fill methods in the CASE industry due to their ease of automation, flexibility, and accuracy.

March 27, 2020

Pilot Chemical Receives Environmental Achievement Award from Ohio Water Environment Association

Cincinnati-based Pilot Chemical earned the Karl G. Voelkel Industry Award for wastewater improvements and accomplishments at its plant in Middletown, Ohio.

March 9, 2020

Cool Customers: Premixed and Frozen Packages for Adhesives and Sealants

Premixed and frozen packages provide highly reliable convenience packaging for plural-component resins.

March 5, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing