Home » ultraviolet (UV) curing

Articles Tagged with ''ultraviolet (UV) curing''

Market Trends

Growth in the UV-curable ink market is being spurred by increased use in food and beverage packaging.

Read More

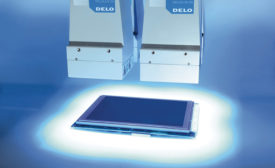

Curing Adhesives: When Less Intensity Is More

More intensive curing lamps can accelerate the production process of light-curing adhesives, but only up to certain limits.

February 1, 2016

Top 5 News that Sticks

Readers Most Interested in 3M Sales Announcement

News about 3M selling its foam adhesive business garnered the most reader interest.

February 1, 2016

Using Multi-Zone Irradiance Control in UV LED Systems

Advancements with innovative technology in LED arrays provide advantages to products with multilinear surfaces.

October 1, 2015

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing