Lightweighting Spurs Growth in Global Automotive Adhesive Tapes Market

Image of a market graph

Straits Research has released a new report on the market for automotive adhesive tapes that estimates the market will reach $13,779 million by 2031. Among the factors responsible for the increased demand for automotive adhesives tapes is the growing move toward automotive lightweighting, in which automotive adhesive tapes play a key role.

Automotive adhesive tapes are a class of heavy-duty adhesive tapes that are primarily used for binding, wrapping, and as a protective layer for the interior and exterior of any automotive product. These tapes help automotive manufacturers increase rigidity and bond longevity, reduce noise, and improve fuel efficiency and user experience. Compared to the traditional nut, bolt, and screw used in manufacturing, automotive adhesive tapes help reduce the vehicle's weight, eliminate noise, and reduce maintenance needs.

Demand for Lightweight Vehicles

According to Straits Research, “The global automotive adhesive tapes market size was valued at $8,645.6 million in 2022. It is projected to reach $13,778.8 million by 2031, growing at a CAGR of 6.45% during the forecast period (2023–2031).” Due to the high gas prices worldwide, customers are increasingly demanding better fuel efficiency from their vehicles. The automotive industry has noticed this and begun substituting adhesive tapes for nuts, bolts, and screws where necessary. According to a U.S. Department of Energy study, a 10% reduction in an automobile's weight can increase fuel efficiency by 6-8%. Automotive adhesive tapes can be used with conventional mechanical fasteners to reduce weight and fuel consumption and lower maintenance costs. Tapes produce higher quality output at a lower cost with little training required. In addition, unlike fasteners, which only distribute holding power where they are installed, adhesives distribute holding power along the entire bond line.

Environmentally Friendly Solutions

Sustainability has become a top priority for brands across industries as consumers have shifted their purchasing habits to be more environmentally conscious. It is now essential for automakers to demonstrate their commitment to sustainability, given the connection between gas-powered vehicles and climate change. Manufacturers are primarily focused on finding environmentally friendly alternatives to solvents. As opposed to mechanical fasteners, green adhesives produce a stronger and more long-lasting bond for automobiles because they are rust-free and less likely to be penetrated by water and snow.

Regional Analysis

According to the study, Europe is the most significant shareholder in the global automotive adhesive tapes market and is expected to grow at a CAGR of 5.8% during the forecast period. The more significant share is related to European manufacturers’ high adoption of automotive adhesive tapes and the rising output of electric and hybrid vehicles. The market is expanding as a result of the presence of luxury car producers in the area. These manufacturers use automotive adhesive tapes to finish automotive products more smoothly and improve the appearance of vehicles from the inside and outside. As a result, there is an increase in R&D in the area to meet the growing demand for more affordable and long-lasting automotive tapes. Additionally, the use of automotive tapes will increase as sales of luxury cars in developed nations grow, which will fuel the expansion of the automotive adhesive tapes market in the area.

Asia-Pacific is expected to generate $2,420.8 million during the forecast period. According to the study, large-scale manufacturing facilities in China are responsible for the high growth rate. Due to economic factors like easy access to raw materials, reasonably priced transportation, and skilled labor, many automotive adhesive tape manufacturers are shifting their manufacturing to developing nations like China, India, Indonesia, Taiwan, and the Philippines. The development of the automotive adhesive tape market will be positively impacted by the growth of the automotive industry and the increasing acceptance of lightweight vehicles. The region's market will grow as China and India become the world's two leading automotive manufacturers.

Key Highlights

Based on type, the global automotive adhesive tapes market is bifurcated into acrylic foam tape, double-sided tape, silicone rubber tape, polyurethane foam tape, and pressure-sensitive adhesive tape. The acrylic foam tape segment is the highest contributor to the market.

Based on function, the global automotive adhesive tapes market is bifurcated into bonding and joining, harness wrap, protective masking, and acoustic and thermal management. The masking segment is the highest contributor to the market, as all coating and repair processes require masking.

Based on adhesive chemistry, the global automotive adhesive tapes market is bifurcated into solvent, emulsion, hot melt, and radiation. The solvent adhesive segment is the highest contributor to the market and is expected to grow at a CAGR of 4.8% during the forecast period.

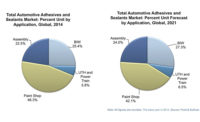

Based on application, the global automotive adhesive tape market is bifurcated into interior attachments, exterior, wire harnessing, and electric vehicles. The interior attachment segment is the highest contributor to the market and is expected to grow at a CAGR of 3.4% during the forecast period.

For additional information about the report, visit https://straitsresearch.com/report/automotive-adhesive-tapes-market/segmentation.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!