Fraunhofer Scientists Develop Adhesives from Feathers

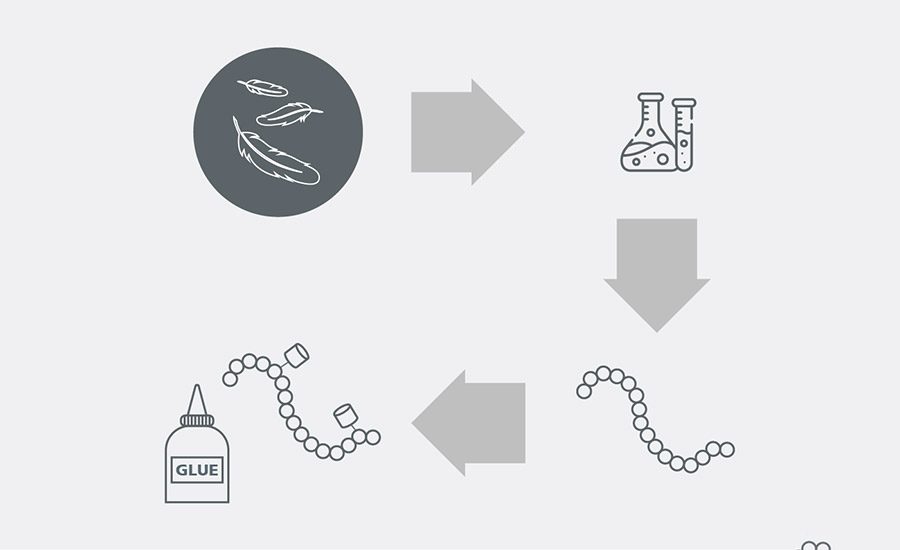

A new process creates specialty chemicals from customized functional keratin proteins derived from chicken feathers.

NikonShutterman / iStock / Getty Images Plus

Feathers contain keratin, a structural protein insoluble in water that can be used to manufacture adhesives. © Fraunhofer IGB

The keratin polymers are enzymatically hydrolyzed into short-chain, soluble oligomers, which can then be processed further to make adhesives and other specialty chemicals. © Fraunhofer IGB

The process was scaled up at Fraunhofer CBP, where several kilograms of chicken feathers were processed. © Fraunhofer IGB

Adhesives are almost always based on fossil raw materials such as petroleum. Researchers at Fraunhofer have recently developed a process that allows to utilize keratin for this purpose. This highly versatile protein compound can be found, for instance, in chicken feathers. Not only can it be used to manufacture a host of different adhesives for a variety of applications, but the processes and end products are also sustainable and follow the basic principles underlying a bioinspired circular economy. The project was developed together with Henkel AG & Co. KGaA.

Adhesives are found nearly everywhere and bond almost every imaginable material to another. They are increasing in popularity as they weigh very little and so lend themselves to lightweight design. Surfaces bonded with adhesive do not warp because, unlike with screw fastenings, the load is distributed evenly. Adhesives do not rust, and seal out moisture. Surfaces bonded with adhesive are also less susceptible to vibration. Added to which, adhesives are inexpensive and relatively easy to work with.

Feathers as Base Material

Traditionally, adhesives have almost always been made from fossil raw materials such as petroleum. The Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB has recently adopted a different approach. Researchers there have been using feathers as a base material instead of petroleum. Feathers are a by-product of poultry meat production. They are destroyed or mixed into animal feed. But feathers are far too valuable to go to waste because they contain the structural protein keratin. This biopolymer is found in animals and makes up talons, claws, hooves, or feathers. Its fibrous structure is extremely strong.

Why Keratin?

Keratin is a biodegradable and thus eco-friendly material whose structure has specific properties that make it particularly suitable for the manufacture of adhesives. Keratin's polymer structure, i.e., its very long-chain molecules, as well as its ability to undergo cross-linking reactions predestine it for the manufacture of various adhesives. "The properties required for adhesives are to some extent already inherent in the base material and only need to be unlocked, modified and activated," explains project manager Dr. Michael Richter.

Platform Chemical and Specialty Adhesives

Over the past three years, Fraunhofer IGB has been working with Henkel AG & Co. KGaA on the KERAbond project: "Specialty chemicals from customized functional keratin proteins." Kera is short for keratin, combined with the English word bond. The partners in the project have recently developed and refined a new process. In the first stage, feathers received from the slaughterhouse are sterilized, washed and mechanically shredded. Next, an enzyme process splits the long-chain biopolymers or protein chains into short-chain polymers by means of hydrolysis.

The output product is a platform chemical that can serve as a base material for further development of specially formulated adhesives. "We use the process and the platform chemical as a 'toolbox' to integrate bio-enhanced properties into the end product," said Richter. This means parameters can be specified for the target special adhesive such as curing time, elasticity, thermal properties or strength. Also, it's not just adhesives that are easy to manufacture but also related substances such as hardeners, coatings, or primers.

In the next stage, the Fraunhofer team set about converting the feathers on a large scale. Ramping up the process fell to the Fraunhofer Center for Chemical-Biotechnological Processes CBP in Leuna. The aim was to prove that the keratin-based platform chemicals can also be manufactured cost-efficiently on an industrial scale. This involved processing several kilograms of chicken feathers, with the material produced being used for promising initial material trials at Fraunhofer IGB and Henkel.

A Bioinspired Economy

This bioinspired process is of particular significance for the Fraunhofer-Gesellschaft. This is not just because it involves biodegradable raw materials or particularly efficient manufacturing methods. Biotechnology is in fact one of the main fields of research for the Fraunhofer-Gesellschaft. Richter explains the underlying concept: "We draw our inspiration from functionality or properties that already exist in nature or in natural raw materials. And we attempt to translate these properties into products through innovative manufacturing methods. This generates a bioinspired cycle for valuable raw materials."

Fraunhofer IGB has been active in all aspects of the bioeconomy for some years and has developed exclusive expertise when it comes to keratin, for example. Which is why chemicals company Henkel approached Fraunhofer IGB for this project. The project carries some economic weight. According to Statista, around one million tons of adhesives were manufactured in Germany alone in 2019. Total value is around €1.87 billion.

And the scientific output is also on point: A patent application has been filed for the new process and an article published in a scientific journal. Two PhD students who have conducted extensive research on the project at Henkel and Fraunhofer are expected to complete their theses around the first quarter of 2024. This new keratin-based technology will allow a host of platform chemicals to be produced in a sustainable, bioinspired way.

The KERAbond project has been funded and supported over the past three years by Fachagentur Nachwachsende Rohstoffe (FNR) in Gülzow on behalf of the Federal Ministry of Food and Agriculture (BMEL) under the Renewable Resources Funding funding program (grant number 22014218).

Article courtesy of Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB. Learn more about Fraunhofer at www.fraunhofer.de/en.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!