Unlocking Efficiency: The Advantages of Peristaltic Pumps

Nostal6ie / iStock / Getty Images Plus via Getty Images

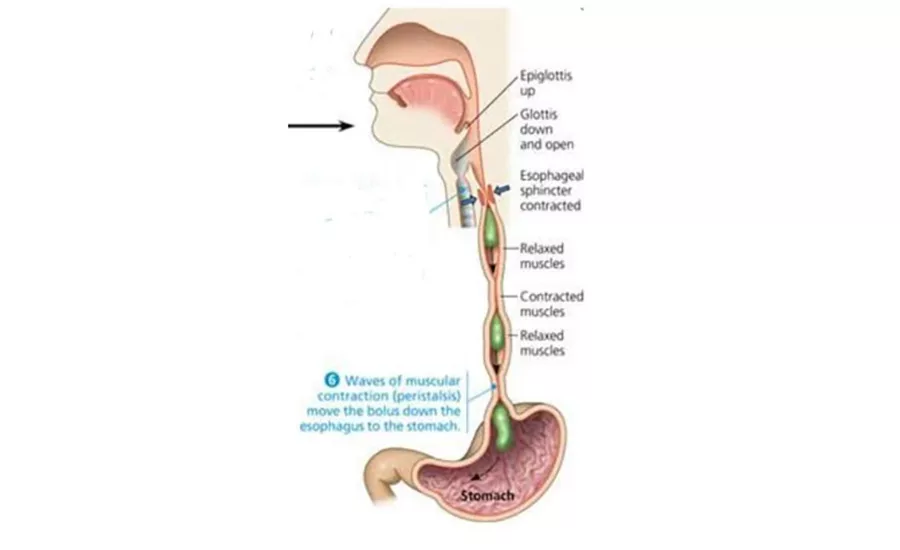

Peristaltic Pumps: Mirroring the digestive tract's efficiency in fluid movement.

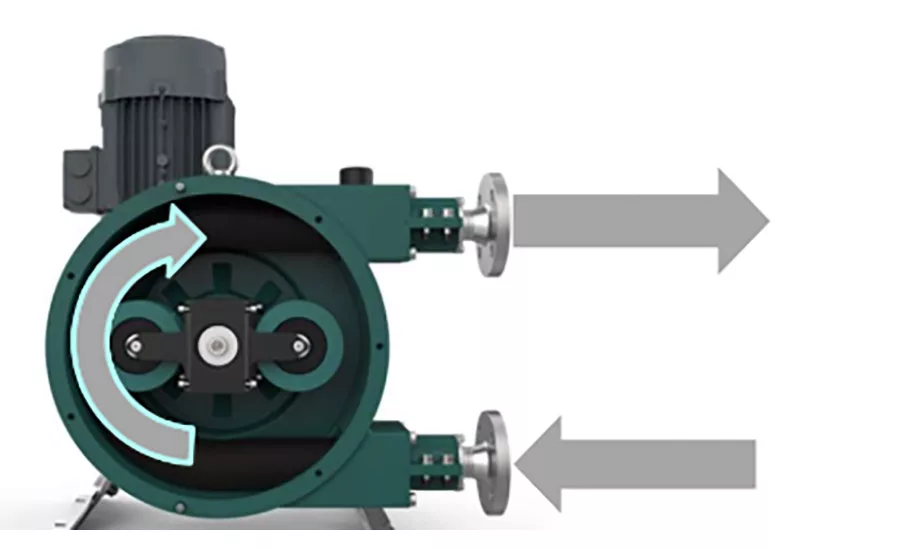

Rollers compress and relax the hose, creating a self-priming, no-slip flow that guides the product seamlessly through the pump to discharge.

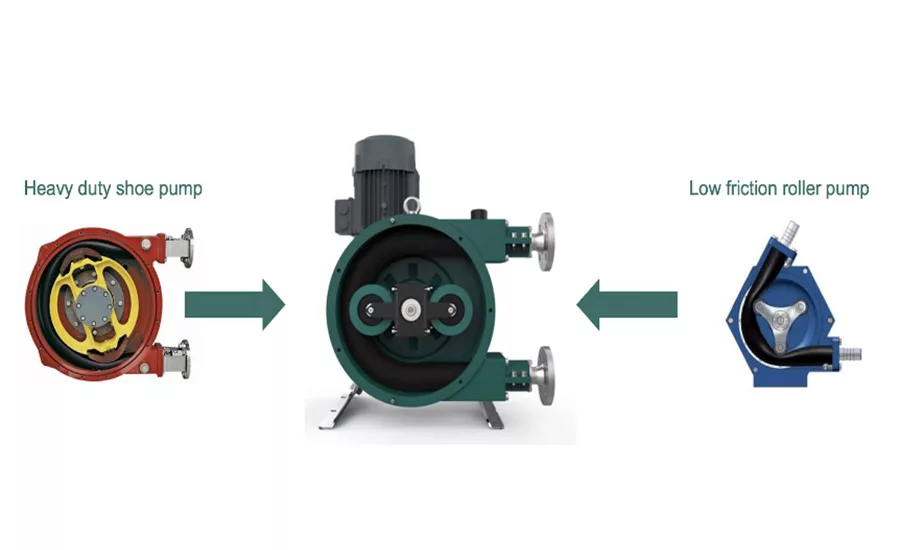

Engineered for 24/7 high-pressure applications, PERIPRO® peristaltic pumps merge the strength of a heavy-duty shoe pump with the efficiency of a low-friction roller pump.

Peristaltic pumps have emerged as a revolutionary solution in industrial pumping, offering myriad benefits over traditional pump technologies. Fundamental to these pumps is a simple yet ingenious component: the hose. By using advanced hose designs, these pumps can significantly increase longevity and decrease operational costs. Let's explore how these innovative pumps are reshaping industrial pumping and driving efficiency across a range of applications.

Utilizing Peristalsis

Peristaltic pumps, operating on the principle of peristalsis, offer a unique set of advantages in the realm of industrial pumping. Mimicking the human digestive system, these pumps gently propel fluids through a system by compressing and relaxing a flexible hose. This design provides several key benefits over traditional pump technologies.

Peristaltic pumps are known for their gentle pumping action, making them ideal for handling shear-sensitive fluids and delicate media. This feature ensures that product integrity is maintained, making them a popular choice in industries such as pharmaceuticals, food, and mineral processing. In an industry where precise metering and gentle handling of sensitive fluid components are critical for ensuring product quality and consistency, peristaltic pumps excel, providing accurate and reliable pumping without compromising the integrity of the product. Similarly, in industries where maintaining the texture and quality of products is important, peristaltic pumps offer an ideal solution. Their gentle pumping action minimizes shear forces, ensuring that delicate products are handled with care. This not only improves product quality but also reduces waste and increases yield, leading to significant cost savings for manufacturers. In the mineral processing industry, often the mineral product slurries cannot be crushed, ground-up or damaged in any way after they have been produced.

One of the most significant advantages of peristaltic pumps is their high abrasion resistance. The design of these pumps minimizes contact between the pumped fluid and the pump components, reducing wear and tear and extending the life of both the pump and the hose. For industries handling abrasive materials, this durability is crucial for maintaining consistent and reliable operation. Traditional pump technologies often suffer from rapid wear of the multiple wetted metal parts and require frequent maintenance and replacement of components. However, peristaltic pumps with advanced hose designs can withstand the harshest operating conditions, resulting in reduced downtime and lower maintenance costs. For example, in mining applications where pumps are exposed to highly abrasive slurries, peristaltic pumps with abrasion-resistant hoses can significantly extend service intervals, reducing the need for frequent maintenance and parts replacement. Similarly, in situations where pumps are required to handle corrosive chemicals and abrasive solids, peristaltic pumps offer unmatched reliability and durability. By minimizing wear and tear on pump components, these pumps help operators reduce maintenance costs and increase overall efficiency.

Peristaltic pumps are also incredibly versatile, and capable of handling a wide range of fluids, including corrosive chemicals, viscous slurries, and abrasive materials. This versatility makes them well-suited for use in various industries. For example, in chemical processing plants, where a broad assortment of corrosive chemicals is used in manufacturing processes, peristaltic pumps offer a good solution. Their seal-free design and a variety of compatible elastomers make them suitable for handling even the most aggressive chemicals, ensuring reliable and efficient operation. Their ability to handle a variety of fluids with ease makes them an indispensable tool for operators looking to maximize efficiency and minimize downtime. Whether pumping corrosive acids, viscous slurries, or abrasive materials, peristaltic pumps deliver consistent and reliable performance, ensuring smooth operation in even the most challenging environments.

Another key advantage of peristaltic pumps is their dry running capability. Unlike many traditional pump technologies, peristaltic pumps can run dry indefinitely without risk of damage. This reliability reduces the need for complex monitoring systems, making them a cost-effective and low-maintenance option. For industries where downtime is not an option, this dry running capability is invaluable. Their ability to run dry indefinitely ensures uninterrupted operation, even in the event of unexpected shutdowns or process interruptions such as a closed valve or a low supply tank level.

With only one wear part, the hose, peristaltic pumps are easy to maintain and repair. Routine maintenance tasks can be performed quickly and easily by onsite personnel, eliminating the need for specialized technicians which reduces downtime. This simplicity and ease of maintenance make peristaltic pumps an attractive option for many industries. By eliminating the need for specialized technicians and reducing downtime, these pumps help operators maximize efficiency and minimize operating costs. Whether pumping corrosive chemicals, abrasive slurries, or viscous fluids, peristaltic pumps deliver consistent and reliable performance, ensuring smooth operation in even the most demanding applications.

Design Offers Durability, Versatility, and Reliability

Requiring minimal maintenance, with only the elastomer hose needing replacement when necessary, NETZSCH PERIPRO® peristaltic pumps offer several additional advantages over traditional peristaltic pump designs. With an innovative roller design and a choice of four elastomers, including EPDM, natural rubber, NBR, and Hypalon, these pumps are suitable for various industrial applications. They are engineered for durability, with heavy-duty rollers and oversized shaft bearings that are designed to withstand the rigors of 24/7 operation and not require maintenance or replacement. A seal-free design eliminates the risk of seal failure, removing the chance of hazardous or volatile chemicals being released because of a failed seal.

These pumps can handle up to 70% solids, making them very suitable for pumping slurries and other high-solid content fluids. With their compact design, NETZSCH peristaltic pumps are desirable for applications where space is limited, allowing for easy installation in tight spaces.

Peristaltic pumps have numerous advantages over traditional pump technologies. With their gentle pumping action, high durability, and versatile performance, they are a good choice for a wide range of industrial applications. Whether you need to pump corrosive chemicals, abrasive slurries, or shear-sensitive fluids, peristaltic pumps deliver reliable performance.

Learn more at https://pumps-systems.netzsch.com/en-US.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!