STRATEGIC SOLUTIONS: Sustainable Solutions

“Sustainability is changing the way products are being designed, produced and discarded. It will certainly change the way we think about the raw materials that go into these products, and it will certainly have a major effect on the adhesives and sealants industry.”1

These days, sustainability affects everyone. It becomes

especially important when adhesives and sealants, as typical representatives of

cross-sectional technologies, are considered. In fact, both adhesives and

sealants are prominent examples of enabling bonding techniques, which allow for

improved sustainability in the first place. Consider lightweight and

fuel-efficient cars and airplanes; wind and photovoltaic energy generation, sun

heating and cooling, façade and glass insulation technologies; and the assembly

of components based on dissimilar materials - adhesives and sealants play an

important role in enabling more resource-efficient solutions at reasonable

costs for them all (and many others). In fact, the “indirect” footprint of

adhesives and sealants (by a magnitude of 100 to more than 1,000) dominates

over the “direct” impact through its composition and its specific use of

chemical resources for producing its base components, as well as energy

requirements for producing, shipping, packaging, and warehousing them.

These days, sustainability affects everyone. It becomes

especially important when adhesives and sealants, as typical representatives of

cross-sectional technologies, are considered. In fact, both adhesives and

sealants are prominent examples of enabling bonding techniques, which allow for

improved sustainability in the first place. Consider lightweight and

fuel-efficient cars and airplanes; wind and photovoltaic energy generation, sun

heating and cooling, façade and glass insulation technologies; and the assembly

of components based on dissimilar materials - adhesives and sealants play an

important role in enabling more resource-efficient solutions at reasonable

costs for them all (and many others). In fact, the “indirect” footprint of

adhesives and sealants (by a magnitude of 100 to more than 1,000) dominates

over the “direct” impact through its composition and its specific use of

chemical resources for producing its base components, as well as energy

requirements for producing, shipping, packaging, and warehousing them.

The “indirect” impact is very specific and can by no means be generalized or quantified; however, it is magnitudes larger than the direct footprint. Consequently, adhesives and sealants manufacturers must provide the best-performing product for a specific use area, a guaranteed life expectancy of the bonded system regardless of physical or chemical attacks as specified, and the respective assembly conditions at the beginning of the lifecycle, including affordable recycling without down-cycling at their end. Only after achieving this challenging set of goals - without any compromise on given HSE requirements - can the question be addressed: to what extent can the same product performance be achieved by further reducing the ecological footprint of the adhesives or sealants formulation itself?

The route to achieve that is diverse, and may include lowering the amount of adhesive per bond through performance improvements, the lowering or total elimination of primering steps for surface preparation, the reduction of packaging and transportation needs, and/or the substitution of materials against those with a knowingly better sustainability performance. Bonding is, in most cases, the preferred joining technique and offers the lowest overall footprint. In the future, attention will be needed to define, specify and quantify what sustainability and carbon foot printing is all about, and to provide assistance to unbiased lifecycle assessments.

When discussing adhesives’ and sealants’ sustainability improvements, the usage of raw materials based on natural or renewable resources (as opposed to depletable sources such as crude oil, natural gas, and coal) is usually considered. However, many forget that only about 0.006% of crude oil equivalents relative to total output is used for manufacturing and formulating the global tonnage of about 10.3 kt (dry) of adhesives and sealants forecast for 2010.2 What’s more, structural adhesion and structural sealing, the two most demanding and fastest-growing segments within the industry, call for ever more sophisticated, better-defined, and repeatable chemistries than Mother Nature can provide.

Adhesives and sealants are, in effect, applied polymers.

They began their success story with rapid progress in macromolecular chemistry

in the 1920s and 1930s, and have since been developed into highly specialized,

partly reactive systems specifically profiled for a very narrow field of

application. Performance as required is paramount, and meeting of all HSE

requirements a prerequisite. Thus, the use of renewable resources has declined

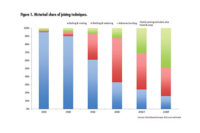

over time since 1920, as the figure indicates.

Adhesives and sealants are, in effect, applied polymers.

They began their success story with rapid progress in macromolecular chemistry

in the 1920s and 1930s, and have since been developed into highly specialized,

partly reactive systems specifically profiled for a very narrow field of

application. Performance as required is paramount, and meeting of all HSE

requirements a prerequisite. Thus, the use of renewable resources has declined

over time since 1920, as the figure indicates.

Raw materials based on natural sources have enabled interesting performance characteristics, but they play a larger role only in low-to-medium modulus application fields. Even in these applications, a chemical modification is often needed to overcome natural quality fluctuations. The table shows benefits and typical use areas of these materials.3

Currently, the use of natural-based raw materials will remain limited, and will not be an option for high-performing structural applications. A realistic route for reducing the “direct” carbon footprint could, under those circumstances, open up with the enzymatic or catalytic breakup of biomass materials, preferably agricultural waste not directly competing with human and animal food. Nonetheless, responsible adhesives and sealants formulators are working to reduce the relative carbon footprint, such as by replacing solvent-based systems with water-based ones, lifting the solid content, improving the robustness of given solutions, and thriving for more performance with less material. Regulators and government authorities contribute to the ongoing evolution as well, and continue to be one of the most important sources for innovation. Better insight in bioengineering may one day change this scenario, namely through green chemistry. For the time being, however, our industry will remain dependent upon petro chemistry. In contrast, the adhesives and sealants industry, through its enabling role, is contributing a lot to truly substantial cutbacks of footprints across all markets - including transportation, aerospace, woodworking, packaging, energy generation, electronics and construction, which in total represent more than 90% of all CO2 emitted by man. This is something to be proud of!

For more information, visit www.chemquest.com.

Table.

The “indirect” impact is very specific and can by no means be generalized or quantified; however, it is magnitudes larger than the direct footprint. Consequently, adhesives and sealants manufacturers must provide the best-performing product for a specific use area, a guaranteed life expectancy of the bonded system regardless of physical or chemical attacks as specified, and the respective assembly conditions at the beginning of the lifecycle, including affordable recycling without down-cycling at their end. Only after achieving this challenging set of goals - without any compromise on given HSE requirements - can the question be addressed: to what extent can the same product performance be achieved by further reducing the ecological footprint of the adhesives or sealants formulation itself?

The route to achieve that is diverse, and may include lowering the amount of adhesive per bond through performance improvements, the lowering or total elimination of primering steps for surface preparation, the reduction of packaging and transportation needs, and/or the substitution of materials against those with a knowingly better sustainability performance. Bonding is, in most cases, the preferred joining technique and offers the lowest overall footprint. In the future, attention will be needed to define, specify and quantify what sustainability and carbon foot printing is all about, and to provide assistance to unbiased lifecycle assessments.

When discussing adhesives’ and sealants’ sustainability improvements, the usage of raw materials based on natural or renewable resources (as opposed to depletable sources such as crude oil, natural gas, and coal) is usually considered. However, many forget that only about 0.006% of crude oil equivalents relative to total output is used for manufacturing and formulating the global tonnage of about 10.3 kt (dry) of adhesives and sealants forecast for 2010.2 What’s more, structural adhesion and structural sealing, the two most demanding and fastest-growing segments within the industry, call for ever more sophisticated, better-defined, and repeatable chemistries than Mother Nature can provide.

Figure. Total Worldwide Production of Adhesives and Sealants, Including Share of Natural-BAsed Components

Raw materials based on natural sources have enabled interesting performance characteristics, but they play a larger role only in low-to-medium modulus application fields. Even in these applications, a chemical modification is often needed to overcome natural quality fluctuations. The table shows benefits and typical use areas of these materials.3

Currently, the use of natural-based raw materials will remain limited, and will not be an option for high-performing structural applications. A realistic route for reducing the “direct” carbon footprint could, under those circumstances, open up with the enzymatic or catalytic breakup of biomass materials, preferably agricultural waste not directly competing with human and animal food. Nonetheless, responsible adhesives and sealants formulators are working to reduce the relative carbon footprint, such as by replacing solvent-based systems with water-based ones, lifting the solid content, improving the robustness of given solutions, and thriving for more performance with less material. Regulators and government authorities contribute to the ongoing evolution as well, and continue to be one of the most important sources for innovation. Better insight in bioengineering may one day change this scenario, namely through green chemistry. For the time being, however, our industry will remain dependent upon petro chemistry. In contrast, the adhesives and sealants industry, through its enabling role, is contributing a lot to truly substantial cutbacks of footprints across all markets - including transportation, aerospace, woodworking, packaging, energy generation, electronics and construction, which in total represent more than 90% of all CO2 emitted by man. This is something to be proud of!

For more information, visit www.chemquest.com.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!