Green Packaging

Potentially hazardous materials require more consideration when packagers are trying to reduce environmental impact.

The term “green” in contemporary parlance refers to an item or activity that demonstrates some ability to reduce its impact on the environment. In packaging, green efforts have often focused on the package and its recyclability, or the amount of recycled material used in the package. Another important aspect is the utilization of package styles that allow the maximum transfer efficiency of the product from the package to the point of use. It is also important to leave behind a package that has minimal environmental impact.

For example, the packaging of aerospace products often requires a high-purity product environment to be maintained in the package. Also, the chemicals in the product may limit the choices available for packaging materials. In those cases where the product basically selects the packaging material to be used, packagers must turn to other methods of reducing environmental impact.

One of the first steps when developing a package for a new material is to consider the hazards associated with that material, as well as the end use of the product. In the aerospace market, the physical demands on the vehicle often necessitate the use of chemicals that can pose hazards to the environment if spillage should occur. The packager must look to innovative designs to achieve greater transfer efficiency and ensure intended engineering performance so that the product goes from the package to the end use with as little loss to the environment as possible while continuing to meet the demands of the respective specification. Understanding the hazards of the product, as well as the final application, enables the packager to envision additional methods of achieving better transfer efficiencies.

In addition to implementing enhanced transfer efficiency, the packager must consider how residues left in the container will be best captured until the container can be suitably disposed of. The packager must also consider a package that will minimize the volume and weight remaining after the package has been used. Different municipalities dispose of hazardous waste by weight or by volume (depending on their waste treatment process), and the packager must try to reduce that environmental footprint on both accounts as well.

The aerosol can provides several benefits as a packaging alternative. Aerosol cans are hermetically sealed, so their contents cannot leak or spill. This dramatically reduces the possibility of an uncontrolled release to the environment. The sealed can also prevents any product contamination, so waste from contamination can be significantly reduced. Aerosols are designed to deliver the right amount of product exactly where it is needed. Through the strategic use of attachments, the product can be delivered precisely and in a controlled manner (even to hard-to-reach places) for maximum transfer efficiencies. In addition, aerosol containers are recyclable; after the product is completely expelled from the can, the aerosol container can be recycled and the metal reused.

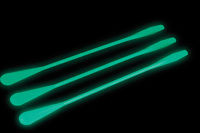

The collapsible pouch or tube has long been in use because it works well in meeting the objectives of the package. The collapsible nature of the package allows better transfer efficiencies compared to the traditional cans or cartridges (especially for thick materials such as greases), as well as lower disposal costs. Cans do not typically offer good transfer efficiencies, since they are dependent on the skill of the user.

While the cartridge package design provides good transfer efficiencies, the resulting container maintains the same volume empty or full. In the case where waste is measured in volumes, cartridges must be treated entirely as hazardous waste and must later be crushed in order to minimize their environmental impact.

In the packaging of aerospace products, the best “green” approach is to minimize waste and exposure to the packaged materials.

For additional information regarding green packaging, contact Andpak Inc. at 400 Jarvis Dr., Morgan Hill, CA 95037; (408) 782-2500; fax (408) 776-3538; or visit www.andpak.com.

The term “green” in contemporary parlance refers to an item or activity that demonstrates some ability to reduce its impact on the environment. In packaging, green efforts have often focused on the package and its recyclability, or the amount of recycled material used in the package. Another important aspect is the utilization of package styles that allow the maximum transfer efficiency of the product from the package to the point of use. It is also important to leave behind a package that has minimal environmental impact.

Aerosol cans are hermetically sealed, so their contents cannot leak or spill.

Aerospace Packaging

Aerospace product packaging is suggested only when it makes sense for guaranteed performance, reduced contamination due to re-entry, encapsulated catalyzed material and the overall impact of minimizing the footprint of hazardous materials. Other features include transfer efficiency and dramatically reduced worker exposure.For example, the packaging of aerospace products often requires a high-purity product environment to be maintained in the package. Also, the chemicals in the product may limit the choices available for packaging materials. In those cases where the product basically selects the packaging material to be used, packagers must turn to other methods of reducing environmental impact.

One of the first steps when developing a package for a new material is to consider the hazards associated with that material, as well as the end use of the product. In the aerospace market, the physical demands on the vehicle often necessitate the use of chemicals that can pose hazards to the environment if spillage should occur. The packager must look to innovative designs to achieve greater transfer efficiency and ensure intended engineering performance so that the product goes from the package to the end use with as little loss to the environment as possible while continuing to meet the demands of the respective specification. Understanding the hazards of the product, as well as the final application, enables the packager to envision additional methods of achieving better transfer efficiencies.

In addition to implementing enhanced transfer efficiency, the packager must consider how residues left in the container will be best captured until the container can be suitably disposed of. The packager must also consider a package that will minimize the volume and weight remaining after the package has been used. Different municipalities dispose of hazardous waste by weight or by volume (depending on their waste treatment process), and the packager must try to reduce that environmental footprint on both accounts as well.

The collapsible pouch allows better transfer efficiencies compared to traditional cans or cartridges.

Real-Life Applications

The aerosol can and the collapsible pouch and tube are examples of packaging that meets the above criteria. The aerosol can has been under scrutiny since the determination that the use of chlorofluorocarbons (CFCs) poses a threat to the destruction of the ozone layer. The phase-out of those products has created various propellants that no longer pose any threat to the ozone layer and can be widely used.The aerosol can provides several benefits as a packaging alternative. Aerosol cans are hermetically sealed, so their contents cannot leak or spill. This dramatically reduces the possibility of an uncontrolled release to the environment. The sealed can also prevents any product contamination, so waste from contamination can be significantly reduced. Aerosols are designed to deliver the right amount of product exactly where it is needed. Through the strategic use of attachments, the product can be delivered precisely and in a controlled manner (even to hard-to-reach places) for maximum transfer efficiencies. In addition, aerosol containers are recyclable; after the product is completely expelled from the can, the aerosol container can be recycled and the metal reused.

The collapsible pouch or tube has long been in use because it works well in meeting the objectives of the package. The collapsible nature of the package allows better transfer efficiencies compared to the traditional cans or cartridges (especially for thick materials such as greases), as well as lower disposal costs. Cans do not typically offer good transfer efficiencies, since they are dependent on the skill of the user.

While the cartridge package design provides good transfer efficiencies, the resulting container maintains the same volume empty or full. In the case where waste is measured in volumes, cartridges must be treated entirely as hazardous waste and must later be crushed in order to minimize their environmental impact.

In the packaging of aerospace products, the best “green” approach is to minimize waste and exposure to the packaged materials.

For additional information regarding green packaging, contact Andpak Inc. at 400 Jarvis Dr., Morgan Hill, CA 95037; (408) 782-2500; fax (408) 776-3538; or visit www.andpak.com.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!