Dispensing Materials in 2K Packaging

Selecting the proper dispensing tool for a dual-component material is crucial for end user success.

Consider the following situation: It is mid-2012, and you are the product development leader for a growing manufacturer of adhesives and sealants. The corporation’s R&D budget has allotted tens of thousands of dollars over the past couple of years for you to formulate the perfect dual-

component (2K) material. After reformulating again and again, you are finally ready to present the final product to upper management and the Sales and Marketing department, along with the rest of the R&D team.

Your confidence is high as you see their jaws drop while reviewing your new 2K material projected on the overhead. The PowerPoint slide shows the MSDS and the TDS, and everyone in the room responds favorably. Now you proudly point out the many incredible attributes of this new 2K material when mixed perfectly according to spec. First of all, this material mixes to become perfectly translucent, but will always cure to the exact the same color as the substrate; it never requires dyes or pigments. It will sand down perfectly—not too ridged, not too flexible, and hard as a rock (unless it is being sanded). It cures at any temperature without moisture, with moisture and even underwater. It is paintable, UV-stable, non-sag on vertical applications, and will “level out” on horizontal applications. It adheres to everything except Jell-O, and actually holds better if you do not clean the dirt and grease from the surface.

Your confidence continues right up to the end of the presentation, when you address questions from your colleagues. The first question comes from someone in the Sales and Marketing department, who says, “I can think of a hundred different markets for this stuff, but tell me, how are we going to dispense it, and how are you going to package it? I noticed on one of those slides that it has a 7.9 to 1.2 mix ratio. Part A is like peanut butter and your activator runs like water. Any industry that I deal with is going to balk, no matter what the benefits might be.”

Even though you have created a miracle adhesive/sealant, it seems as though you have put the cart before the horse—unless your target market is accustomed to (and qualified for) mixing, measuring and applying everything by hand. Requiring manual mixing, or even meter/mix/dispensing, probably cuts your market penetration considerably.

The Total System

When developing a 2K product that is intended (or has the potential) to reach across many markets, it is important to consider the total system, which includes materials, containment unit/cartridge/pistons, nozzle/static mixer, and dispensing system. If a piece of the total system is ignored, the application is likely to fail.

For a successful dispensing application of a 2K material using the total system process, it is a good idea to understand what industry options are available. Several options for dual-component “material containment units” should be kept in mind:

- Part A and Part B sausage systems

- Side-by-side cartridge systems

- Coaxial cartridge systems

- Barrier or injection style kits

- Universal cartridge systems

- Volumes of 50-100 mL

- 0.5-25 mL syringes

- Made of mainly polypropylene/nylon

- Specific mix ratios (mainly 1:1, 2:1, 4:1, 10:1 and limited volume in 3:1 and 5:1)

- Several options are available in nozzles or static mixers for specific materials for successful final applications. Just as with the containment units, static mixers involve several options:

- Standard mixer lengths from 1.5 in. (bayonet) to approximately 22 in.

- Standard element diameters for spiral style from 2.36 mm (bayonet) to 12.65 mm

- Number of mixing elements ranges from seven (bayonet) to 56

- Square style (for higher viscosity materials, or a shorter length is required)

- Stata style for low viscosity materials (not very common)

- Spiral style works with most common size and element options

A number of packaging manufacturers, dispensing tool manufacturers and contract packagers are available to assist in choosing the proper combination of cartridges, cartridge pistons, and static mixers. Many industry individuals have the ability and talent to review your materials and narrow down the many options in order to start the formulator in the right direction.

Even though the tool, cartridge/mixer manufacturers and contract packagers may greatly assist in putting the total system puzzle together, the final decision comes down to the adhesive and sealant manufacturer. After being pointed in the right direction, the material manufacturer is responsible for completing all the necessary testing to approve the final package.

Dispensing 101

The dispensing portion of the total system is often taken for granted. While many manufacturers spend a great deal of time and money putting together all of the pieces for the perfect combination of components, they often blindly throw it into a specific market and leave it up to a distribution network or the end user to determine the right dispensing tools. However, just because a cartridge system fits in somebody’s dual-component gun does not necessarily mean that it will dispense accurately in order for the material to mix/cure properly. Not all dispensing tools are created equal.

Most of the time, the results that an end user experiences when dispensing a 2K product will be a direct reflection of the material and the name that is on the material. The blame for a negative result is rarely placed on the dispensing tool. A dispensing tool can cast either a positive or a negative light on your product. It is for this reason that many 2K and even 1K manufacturers provide the proper tools with their materials.

If your dual-component product is not very forgiving, especially if that mix ratio cannot be altered, then it is crucial to team up with a quality tool manufacturer in order to maintain dispensing accuracy. Determining the optimum force of the drive unit in order to apply the needed pressure to both Part A and Part B for even extrusion is critical. Once this standard is complete, the material manufacturer should push to make sure that the end user chooses the specified tool to achieve best results. Better yet, the material manufacturer should have the tool conveniently available through their chosen marketing channel.

Several elements should be considered when looking for a quality manufacturer of dispensing tools:

- How many years have they been in business, and how many years have they supplied to your market?

- Do they design/engineer their own products, and to what extent?

- Who are their engineers and how long have they been in the area of tool design?

- Do they have any manufacturing in the U.S. in order to support domestic or imported products?

- What are their most technically advanced products, and who maintains them?

- What internal technical services do they provide?

- What products currently show that they are on top of current trends in the marketplace?

- Are they truly a manufacturer themselves, or only a box-in/box-out import company?

- How familiar are they with specific types of 2K product and packaging components?

Choosing the Right Tools

Only a small number of today’s quality dispensing tool manufacturers provide a one-stop shop approach to supply the multitude of market segments in 1K and 2K products. Dual-component tools are almost always built around the style of each cartridge due to the importance of proper cartridge support under heavy pressure when achieving a successful application and preventing cartridge damage.

In most situations, each tool’s carriage (front end) must therefore be customized for the many different cartridge styles and mix ratios. The tool carriage has to work with what is engineered in drive units (back end) and is really the heart of the dispensing tool. It is important to mention that determining how much force a drive unit can create, and then making sure that pressures are accurate on each side of a dual component cartridge, is critical to achieving a proper mix. Drive units are basically of three types: manual, pneumatic and cordless.

Manual

Manual tools are rated by the amount of force they can create, which is produced by the amount of leverage available in the engineering of the handle. This leverage is also called the mechanical advantage; though used as a point-of-measure, it is not necessarily an industry standard.

Most manual dispensing tools are labeled with their respective mechanical advantage. In 2K dispensing tools, the lowest mechanical advantage is about a 12:1 ratio and the highest is about 34:1. A higher mechanical advantage (or more leverage) is not always a good thing.

While you will get more power from a higher leverage trigger, the extrusion rate of the materials can be extremely slow. It is like shifting a vehicle in first gear—you get plenty of power, but not much speed. For example, with a standard 10.3 oz tube of latex caulk, a 12:1 leverage drive unit will dispense about 40% more material per trigger squeeze than an 18:1 leverage drive unit. A contractor will have to squeeze the trigger approximately 33% more times to extrude a tube of caulk using an 18:1 gun than with a 12:1 gun.

The amount of force created by the drive unit determines the pressure on the adhesive or sealant within the cartridge in order to extrude the material. The higher the mechanical advantage, the greater the force, and therefore the greater the pressure on the materials. To calculate pressure on the material within a cartridge, we use the formula: P=F/A. Pressure is determined by drive force divided by area of the plunger that is pushing on the material. For example, if a 2 in. piston in a

10.3 oz cartridge has an area of 3.14 in.2, and a cordless gun creates a force of 950 lbs, then the pressure could be calculated as 950/3.14 = 300 psi. Note that in a dual-component tool and cartridge, the application has two pistons. In order to dispense the material, the pressure must be 300 psi divided by the two pistons, or 150 psi on each piston.

In another example, a 4 in. bulk material dispensing gun piston has an area of 12.56 in.2, and a cordless gun creates a force of 950 lbs. Therefore 950/12.56 = 76 psi. Less drive force is needed because of the smaller diameter. When the diameter is larger, more drive force is needed.

Certain combinations of cartridges, pistons, static mixers and materials may not hold up if the force is too great. Failure in dispensing can occur on a number of levels and in any of the components. In all work environments, the maximum pressure on materials and components should be realized prior to exposure to the end user. Certain materials need to flow at a proper rate through a static mixing nozzle in order to achieve the correct mix. Too much pressure can increase the flow to the point where the material is not moving through the mixer elements properly, and a proper cure will not be realized. Too much force in a poorly engineered manual tool can cause lead-lag results of Part A and Part B. At the end of the day, the total system is only as good as its weakest link.

As mentioned before, there is no industry standard on the calculation of mechanical advantage. Even if a manufacturer of dispensing tools says their product has a 26:1 ratio, the real test is how much force is actually created by the tool. Reputable manufacturers that have the testing equipment will be happy to give you the actual results of any testing needed.

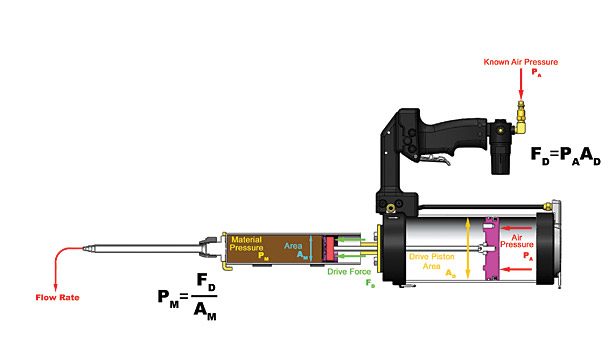

Pneumatic

Air-powered 2K tools are a must when the work is repetitive or the materials are viscous. This type of drive unit provides constant material flow and is a relatively low-cost alternative. An important safety feature in pneumatic dispensing guns is a true air regulator. Not only is the regulator a means of controlling the extrusion rate, but it is critical in only allowing a specified pressure into the air chamber—regardless of what the compressor is pushing. The total system of certain cartridges, pistons and materials can only handle a specific amount of pressure. If the air gun is only equipped with a needle valve to regulate the air, problems could arise. The maximum power created by most professional air dispensing hand tools ranges from about 300-1,500 lbs of force.

The force generated in a pneumatic dispensing gun is based on the amount of air pressure from the compressor that is allowed through the air regulator and the area of the dispensing tools air chamber (see Figure 1, p. 14). Force is created by air pressure in the tool multiplied by the area of the tool’s air chamber. The pressure on the material to extrude can be found by the force divided by the area of each cartridge plunger. For example, if an air regulator allows a maximum of 100 psi into the dispensing gun and has a 4 in. diameter air chamber, which is an area of 12.56 in.2, then the force can be calculated as follows: 100 psi (through the regulator) x 12.56 in.2 (area) = 1256 lbs of force created.

To calculate pressure on the material using a standard 300 x 300 ml 2K cartridge (3.14 in.2 each piston), take 1,256 lbs (force) divided by 3.14 (area of piston) = 400 lbs of pressure. Divide this by two because there are two pistons to arrive at 200 lbs of pressure on each part (A and B).

Pneumatic dual-component tools are available for nearly every application and market that has a need. The majority of options use the dual-component plastic cartridge platform, but current sustainability trends are leading to an increasing use of dual sausage packs as an alternative. Dual-component products for spray applications are also becoming more popular as material manufacturers continue to find endless opportunities; meter/mix pumps have proven to be too expensive, and a 56-oz dual cartridge holds just enough material to get the job complete.

Cordless

A cordless gun can dramatically decrease the amount of time required on a worksite. For example, a 30-oz bulk gun with a 2-in. barrel can fill a ¼-in. x 1/8-in. joint the length of a football field in less than 2 min (more than 150 ft/min). An additional benefit is that, unlike with a pneumatic powered tool, no air compressor hoses get in the way.

Cordless dispensing tools are a viable alternative to manual and pneumatic for a number of reasons:

- Linear motion devices (no pulsation dispensing)

- Rate of extrusion fixed to drive speed, regardless of pressure developed in the cartridge

- Max force devices (won’t exceed the maximum force specified, like an air tool can)

- NiCad and lithium ion batteries (no air compressor hose or hand fatigue issues)

- Linear force range generated is 350-1,200 lbs

- Plunger travel rate from 3-25 in./min

- Most high-viscosity materials do not pose dispensing problems

As battery technology continues to improve, so will the features and benefits of cordless dispensing tools. Most cordless dual- or single-component dispensing guns are equipped with the NiCad battery platform, which ranges from 14.4-20 V options. A new 18 V

lithium ion platform is available for dispensing tools such as single-component cartridges, sausages, bulk and dual-component varieties. Some of the benefits of the 18 V lithium ion battery include:

- 50% lighter than 14.4v NiCad battery

- 40% longer run time with no fade (increased performance)

- Wider operating temperature range (down to 0°F)

- Temperature management system keeps battery in ideal temperature range, providing maximum life

- 50% faster recharge (30 min)

- 50% more recharges (fewer battery purchases)

- Battery fuel gauge displays remaining run time

- Rugged case and internals prevent shock damage

Consistent Quality

Understanding the total system when formulating adhesives and sealants allows a manufacturer to help a product reach its market potential. When it comes to putting the pieces of the puzzle together, many options and resources are available to set the formulator up for success. A formulator should take the many environmental variables into consideration when the end user is dispensing their products. Consistency in the mix has to be maintained, regardless of any environmental factors. The consistency and quality when extruding the final product may not be realized if proper consideration is not given to the tools being used.

The dispensing gun can be a direct reflection of the total package. Therefore, it is important not to leave it up to the end user to make that decision. Although the costs of dispensing tools on a sealing or adhesive project are often less than 1% of the total costs, they represent at least 50% of the success of the application.

For more information, contact Albion Engineering Co. at 1250 N. Church St., Moorestown, NJ 08057; phone (856) 235-6688; or visit www.albioneng.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!