Novel Testing and Quality Control

Distinctive data can help convince customers to allocate time and resources to trial a product in their application.

For many years, the adhesives and sealants industry has used a range of standardized test methods to ensure the quality of products for industrial applications. Laboratories generally embrace these as the cornerstone of lab testing. In order to satisfy the requirements of emerging and niche markets, however, non-traditional testing can employ novel test parameters to provide pertinent data.

Distinctive data can help convince customers to allocate time and resources to trial a product in their application. Some recent examples of this inventive testing include the use of a tensiometer to measure the rate of absorption of a hot melt into wax-coated carton stock; rheological characterization to predict the potential of a water-based adhesive to clog nozzles; measurement with a hybrid rheometer to compare the range of a group of hot melts; and loop tack testing for waterborne adhesives.

TENSIOMETER MEASUREMENTS

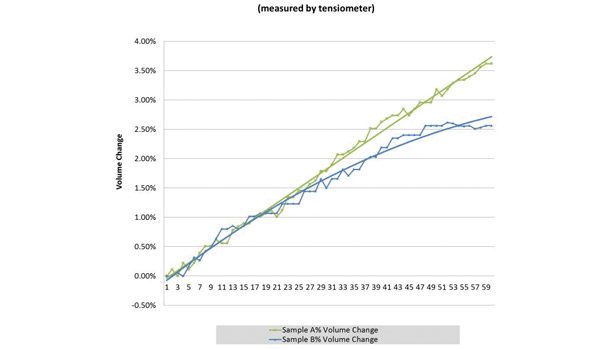

The evaluation of hot-melt adhesion typically relies on the visual evaluation of fiber-tearing bonds. Little information is usually known about the depth of the bond. A bond that appears to give 100% fiber tear can actually be a very weak bond if the hot melt barely penetrates into the surface. Some of the most difficult bonds to evaluate include those on wax-coated corrugated stock, which are typical in meat or poultry packaging.

Tensiometers (or goniometers) are often used to evaluate the wetting of a substrate via contact angle, surface energy or surface tension measurements. While these measurements provide valuable information, they are only an indirect means of measurement and do not predict actual, in-use performance of a particular hot melt on a particular substrate. Custom modification of this instrument allows for a hot melt to be dispensed at a range of temperatures onto a customer’s exact substrate. Real-time measurement of the shape of the drop not only measures contact angle changes over time, but volume changes over time as well. Since hot melts have a negligible content due to volatile compounds (VOCs), the volume change must then be attributed to the absorption rate into a given substrate.

With wax-coated substrates, the absorption rate is critical due to the need for the hot melt to first melt through the wax coating, and then have enough heat left to absorb into the substrate (see Figure 1). The time needed for this absorption can be correlated to the open time of the equipment, so adjustments to formula or equipment can be made to maximize the process yield. Knowing the volume change over time is a valuable tool for predicting product performance at a customer site. This pre-screening gives added confidence that a field trial will have the expected results.

RHEOLOGICAL CHARACTERIZATION

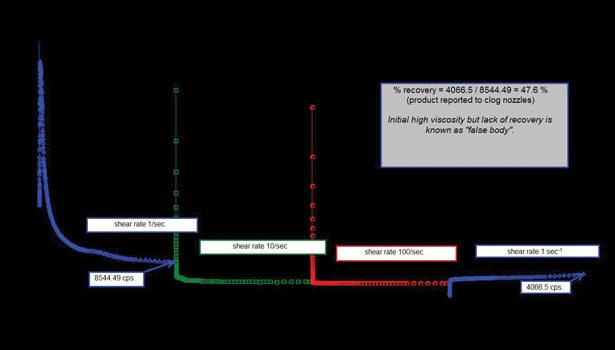

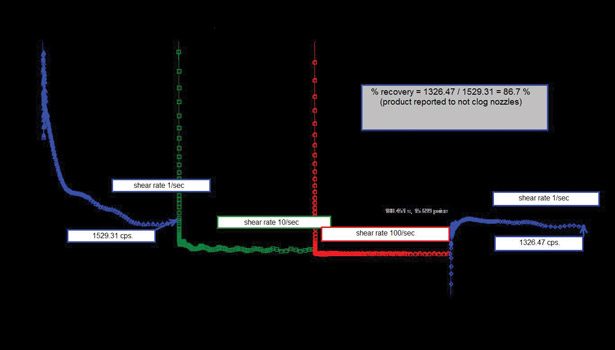

At the 2012 SuperCorr Expo in Atlanta, three equipment manufacturers highlighted three different equipment-related approaches to prevent or minimize the issue of nozzle clogging for waterborne adhesives. This clearly indicates that this is a widespread issue in the industry. An approach for pre-testing in a controlled laboratory setting can substantially increase the rate of success at a customer trial. (Of course, nozzle dry-out can have more than one root cause, such as low humectant levels accelerating the loss of water from the glue, or the dripping of the glue after the pressure cycles off.)

The on/off cycling of a high-speed gluer imparts very high shear rates to any glue. Because a rheometer can impose these high shear rates to glue and then measure the response to that shear, it offers a precise technique to simulate machine conditions (see Figures 2 and 3). Glues that exhibit a rapid increase in viscosity after the removal of the shear can understandably drip less than those with a sluggish viscosity increase. While this is certainly not the only factor contributing to dripping and/or clogging, it can be an important tool in any root cause analysis.

MEASURING WITH A HYBRID RHEOMETER

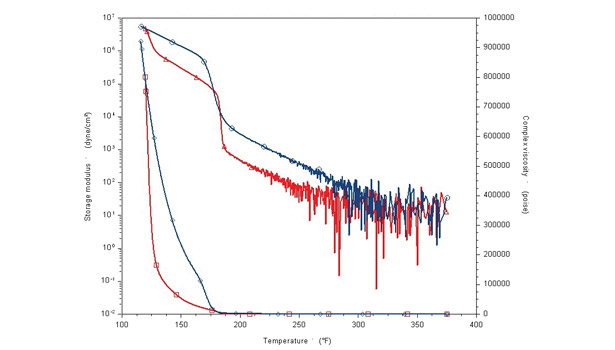

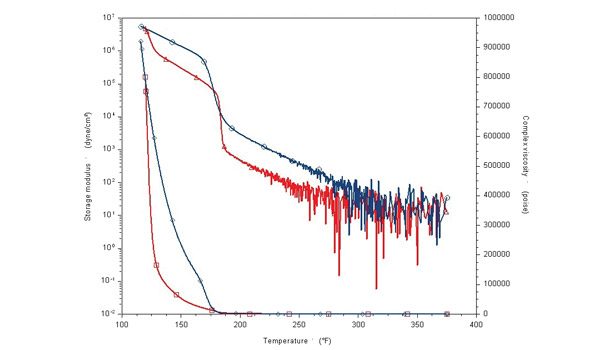

Many hot-melt applications with either a bead or swirl spray for larger surface areas rely on a long product open time. In Figure 4, the sample shown in red will have a longer range, as evidenced both through the delayed viscosity (lower circle) and lower modulus over most of the temperature range tested.

If the range of the current product does not match up with the open time of the user’s process, costly quality issues could arise, eventually leading to the loss of a customer. For example, a long range with a short open time can result in movement between substrates, causing misalignment in the final bond. A shorter range with a longer open time can result in poor adhesion due to pre-cure of the hot melt.

An analysis of a current troublesome product with new potential replacement products on a hybrid rheometer designed for hot melts can ensure that the next product recommendation will at least be a step in the right direction. Both modulus and viscosity can provide a clear picture of the product’s behavior.

LOOP TACK TESTING FOR WATERBORNE ADHESIVES

When comparing the wet tack of waterborne adhesives, it is known that many variables can cloud this determination, making it difficult to relate various products. A non-biased quantitative test can help to establish the relative wet tack of a group of products (see Figure 5). The benefit of this method is that it allows the analyst to use exact customer substrates while closely replicating some of the assembly equipment process parameters.

This test is similar to, and derived from, the ASTM D 6195A Loop Tack Test used for pressure-sensitive adhesives. The main difference is the drawdown of the wet adhesive on the stage of the tensile tester, followed by an instantaneous test initiation. In order to obtain lower standard deviation with test results, it was found that the substrate on the stage of the tensile tester should be rigid and firmly held in place, and the substrate forming the loop should be composed of a very flexible material.

The adaptability of this test allows for changes in stationary substrate material, loop material, loop speed and dwell time. Once this test is properly set up, it is possible to achieve a repeatable test to help reliably differentiate the wet tack between many different adhesives.

FIELD TRIAL SIGNIFICANCE

Field trials command a significant cost commitment from a customer and require a considerable amount of trust between the supplier and the customer. Customers have every right to expect improvements from a trial, including (but not limited to) the following areas: improvement in final yield, increase in processing speed, reduction of cost-in-use, improved long-term reliability, increased safety, or combinations of the above. When laboratories and technical service groups devise and implement predictive testing as a matter of course and can convey preliminary results to a customer, they not only help to justify a field trial, but also increase the likelihood of a successful run.

For more information, visit www.rsindustrial.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!