Strategic Solutions: The Voice of the Customer

Lean manufacturing usually defines “customer” as existing customers who drive your business processes.

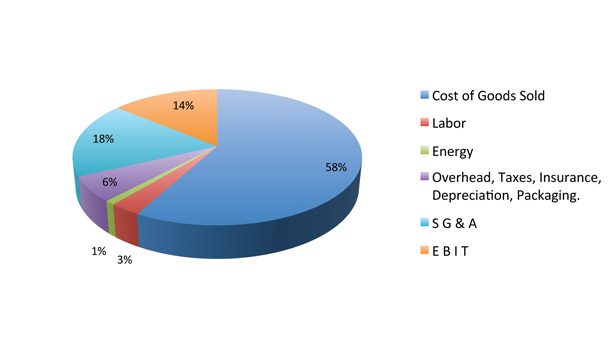

Figure 1. Average U.S. Coating Company Cost Structure

Source: The ChemQuest Group estimates.

Figure 2. Average U.S. Adhesive Company Cost Structure

Source: The ChemQuest Group estimates.

Most manufacturers are currently or have been involved in some form of lean process. Your company may be well down the path or just starting out, or your customers or suppliers may be going lean. The Lean Enterprise Institute characterizes lean as “creating more value for customers with fewer resources.” In other words, lean maintains a strong focus on both the customer and process efficiency.

Because businesses operate for profit, lean is used as a way of reducing costs; logical business people typically look first to the areas where costs are most visible: manufacturing. As Figures 1 and 2 show, manufacturing-related costs overshadow other business costs in our industry. Both charts use data midpoints for clarity, thus the relative size of the pie segments is approximate. Adhesive and coating companies were chosen since many firms have elements of both.

Defining the Customer

Lean manufacturing usually defines “customer” as existing customers who drive your business processes—but is that the definition that your salespeople use? What about marketing, customer and technical service, and leadership—inclusive of the board of directors?

If the customer is at the center of a lean initiative, defining what a customer is and applying the definition to the whole enterprise is a top priority. In addition, if “creating more value for customers” is the core of the mission, then customers’ voices should guide a company’s lean process. Lean needs to begin with the second-largest pie segment, SG&A (Selling, General, and Administrative costs), because most customer interface occurs within that segment. Lean thinking will have the greatest institutional impact if it emanates from the parts of the company that interface with the customers most. If you do not have a corporate definition of “customer” that everyone uses and understands, you will depress growth and profits.

Defining your customer sounds simple. For many companies, this is anyone that shows an interest in what it sells. A refinement of this definition is anyone willing to spend money for what the company sells. A better definition for a lean company would be “someone who values what we repeatedly deliver as our value proposition.” Those could very well be your current customers, but are they also your future customers?

Are you implementing changes to market channels? Selling direct and through stocking distributors presents unique operational challenges. For example, how are you going to provide distribution-like services for direct accounts? What needs do distributors have that differ from direct accounts? Are you expanding geographically? How do customers in Manila differ from your customers in Minneapolis? How do multiple languages and cultures impact your operations?

Listening to the Customer

For the sake of brevity, let us assume that you have clearly defined both your current and future customer (prospect). We are done—congratulations! Everyone can listen to the voice of the customer because we know who they are! Not so fast. Who is speaking for your customer? Purchasing, Engineering, Production and Receiving departments all do, but who is doing the listening for you, and how do you collect and process the information? How often? Which voice is the loudest?

Engineering wants the “best” product, but Purchasing wants the “cheapest” product, and Production wants the exact same properties every time. How do you weigh these factors to provide the best value? Lean processes applied to the interface with the customer will help you bring clarity and actionable steps to the voice of the customer.

Summary

If you think this article asked more questions than it provided answers, you are exactly right. We must ask questions to get the answers we need to meet customer needs with “fewer resources.” Inefficiencies in your customer acquisition and retention process will create inefficiencies in your manufacturing and fulfillment operations.

Build your lean initiative on the foundation of your customers’ voices, and you will drive growth by meeting customer needs better and faster. Define all terminology that guides your business decisions to minimize the inefficiencies of misunderstanding and misdirection and increase profits. Your crisis management skills may start to rust, but your stakeholders will be much happier.

Any views or opinions expressed in this column are those of the author and do not represent those of ASI, its staff, Editorial Advisory Board or BNP Media.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!