Advancing Adhesives: A Natural Feedstock

A new carbon-negative bio-butanol production technology uses cellulose as its feedstock.

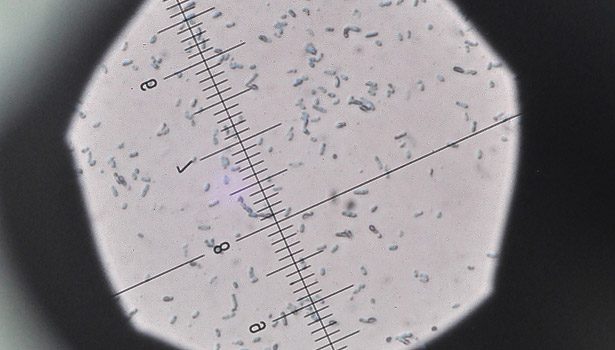

ITRI's proprietary micro-organism contained in beads is shown immersed in fermentation broth.

ITRI (Industrial Technology Research Institute), Taiwan’s largest and a leading international high-tech applied research institution, recently introduced ButyFix, reportedly the first biochemical technology for bio-butanol transportation fuel production with a negative carbon footprint. The technology uses nature’s most abundant biomass—cellulose—as its feedstock, rather than corn. The total energy content in the lignin-rich biomass has the surplus to cover not only the energy for production, but also for the entire lifecycle of the fuel (well-to-wheel). As a result, the greenhouse gas (GHG) emission of the bio-butanol is slightly negative, which is thus very positive for the environment. ButyFix is available for licensing to biofuel and chemical processing organizations.

ButyFix technology can produce bio-butanol with GHG emission reduction of over 100%, much higher than the currently available corn ethanol with a GHG reduction of approximately 23%. If the U.S. replaced corn ethanol with ButyFix butanol based on today’s ethanol consumption of 13 billion gal, it could reportedly further reduce CO2 emissions in the U.S. by 90 million tons a year. Furthermore, butanol produced using ButyFix is the only biofuel that can achieve a transportation-fuel price of $2/gal—well below the current price of gasoline and bio-ethanol—and it requires no government subsidies.

ButyFix bio-butanol can be used to retrofit existing ethanol plants, as a drop-in fuel (surpassing ethanol with its higher heating value), and is reportedly more compatible with current gasoline engines and existing gasoline infrastructure. It can be blended with gasoline to double the current amount of ethanol usage without modification of existing automotive engines. It also can be blended into gasoline in conventional pipelines without corrosion or other water–related issues associated with ethanol blending. It could allow refiners to more quickly meet the EPA’s renewable fuel standards, which mandate that transportation fuels contain increasing amounts of alternative fuels over time.

Although primarily designed as a technology for producing bio-butanol for transportation fuel, ButyFix also has potential applications in the industrial chemical market. For example, the material provides a new technology for synthesizing lower carbon chemicals into higher carbon chemical compounds in an effective manner, creating an easy way to synthesize chemical compounds. Other potential applications include chemical agents, raw materials, intermediates, or solvents for the production of paints, adhesives, and detergents. The use of ButyFix bio-butanol as a raw material to derive butyl acrylate is especially promising, because this important chemical is currently mostly derived from petroleum, and ButyFix can improve the environmental impact over petroleum as a green technology.

Production Process

The ButyFix bio-butanol production process consists of three steps. First, cellulose and hemicellulose are converted into sugars by an eco-friendly chemical solvent in the hydrolysis. Next, sugars are converted into butyrate in a fermentation procedure. Finally, butyrate is chemically converted by way of esterification and hydrogenation into butanol. The microorganism goes down a different metabolic pathway that can “re-use” the carbon dioxide generated in the fermentation, resulting in the high carbon fixation performance of ButyFix.

ITRI developed and refined the ButyFix bio-butanol production process to a point where it now produces the industry’s smallest possible carbon footprint and greenest biofuel. ButyFix has achieved a butyrate yield of 0.70 g/g-sugar, which is 94% of carbon conversion and 2.7 times higher in carbon conversion than the traditional acetone-butanol-ethanol (ABE) process. ButyFix has a theoretical maximum carbon yield of 100%, meaning that all carbon can be fixed by fermentation if the production is optimized. By contrast, all other current bio-fuel fermentation processes have a theoretical maximum carbon conversion yield of 67% because of CO2 emissions in fermentation. Carbon-fixation performance is the most important factor to consider when deciding which biofuel technology best serves carbon reduction; the best technology produces the smallest carbon footprint by emitting the least or fixing the most carbon.

“ButyFix has high potential to solve many current environmental and transportation fuel problems with a green, carbon-negative, energy-efficient bio-butanol production process that can be deployed anywhere in the world,” said Alex Tong, Ph.D., vice president and general director, Green Energy and Environment Research Laboratories, ITRI. “ITRI looks forward to working with ethanol and other fuel production and chemical processing organizations worldwide to significantly reduce our global carbon footprint, simplify butanol production and delivery processes, increase biofuel profit margins, and improve biofuel efficiency.”

In addition to having the smallest, negative, carbon footprint of all biofuels, other benefits of ButyFix bio-butanol include:

• Can be produced by retrofitting existing ethanol production facilities, which drastically reduces the capital investment requirement for production

• Can increase manufacturers’ profit margins by 20-30% over ethanol

• Contains approximately 30% more energy than ethanol and almost as much energy as gasoline, with fuel consumption and refill requirements more comparable to gasoline than to ethanol

• Can be increasingly blended with gasoline to scale with increasing demand and production volumes

• Is cheaper than current mainstream bio-ethanol; and given a sufficient volume, is cheaper than gasoline

• Is eco-solvent and less corrosive on equipment than ethanol, resulting in equipment cost savings

• Produces a homogeneous, faster reaction, with easier process control and production scaling than ethanol

• Requires lower production temperature and pressure than ethanol for lower energy consumption, lower equipment costs, and fewer inhibitors to the fermentation process

Commercialization of ButyFix is currently under way. The technology is available for transfer to companies worldwide. ITRI holds four patents and six pending patents internationally on ButyFix technology, including in Taiwan, China, and the U.S.

For more information, phone (408) 428-9988, email 0800@itri.org.tw or visit http://www.itri.org.tw/eng.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!