Strategic Solutions: Surface Treatment - A Formulator's Friend for Adhesives, Sealants and Coatings

A well-chosen and implemented solution allows manufacturers—and their customers—to focus on the next challenge.

As a supplier, imagine knowing that almost any material was bondable. How much more productive would your work be if you could focus on such factors as environmental resistance, structural strength or cure speed? Imagine not needing to reformulate when your customer changes material specifications or vendors. How much more efficient would you be if you were not fielding calls about random “failures”? What if the substrates and surfaces you bond are as controlled as fit tolerances? Tools exist to make most of these things possible.

Parts cleaning offers many benefits; for the purpose of this discussion, let’s focus on hard-to-bond surfaces, where cleanliness is critical for all high-performance applications. Chemical options such as primers and etchants exist, but we will limit ourselves to “dry” processes.

While the following systems can be as inexpensive as a few thousand dollars or as much as hundreds of thousands of dollars, they are all relatively inexpensive on a per-part basis. A well-chosen and implemented solution will be economical and robust in use, and should allow you and your customer to focus on the next challenge. Even systems that consume energy or process gases have a low incremental cost in most production environments.

Flame Treatment Systems

Flame treatment is a process with which most of us are familiar. It wouldn’t surprise me to learn that our ancestors flame-treated cave walls to make pigments adhere better for their paintings. Most of us have grabbed a propane torch on our bench to treat a polypropylene widget to enhance adhesion. Flame treatment is often used for large, three-dimensional parts due to a relatively low capital cost and customizable burner configurations.

According to Dom Medina, president of Flynn Burner, while standard configurations of burners are available, including handheld treaters, the majority are custom-designed for automated lines. Flame treatment is best used with adhesive systems that wet well. Typical activity levels achieved are in the 50 dyne range. Some people have concern about open flame systems, but these concerns can be managed. I have witnessed flame systems treating polyolefin shotgun shell casings for printing in a plant full of gunpowder.

Corona Discharge (Plasma) Systems

Corona discharge (plasma) systems are treatment systems using high-voltage electricity to create a corona discharge to activate the surface. These systems excel at treating roll-fed sheet stock. In addition to activating the surface for adhesion, the ion field neutralizes static, releasing dust and particulate contaminants that can spoil the assembly as inclusions.

While these systems produce ozone, solutions in the form of ozone catalyst equipment turn ozone into oxygen. Lower levels of ozone can also be stack ventilated. The ability to sequence the corona generators and work from a single power supply enables the wide format necessary for treating wide stock. They pair well with ribbon, curtain or spray coating applications.

Plasma Jet Systems

Unlike corona systems, plasma jet systems do not expose the part to high voltage. This reduces the risk of electrical shock and allows their use on conductive substrates like carbon fiber and aluminum. Due to the nozzle configuration, these are best for discreet area treatment like gasket channels or elastomeric profiles. It is possible to treat one area for bonding or coating and enjoy the lubricity and release properties of the substrate in other areas.

Built-in process monitoring and simple robotic integration make these tools viable companions to automatic adhesive application. Reactive hot-melt polyurethane (PU)-bonded headlight assemblies made with polypropylene housings have been used for years because of plasma treatment. Treated elastomeric seals accept slip coatings and flocking for automotive door seals.

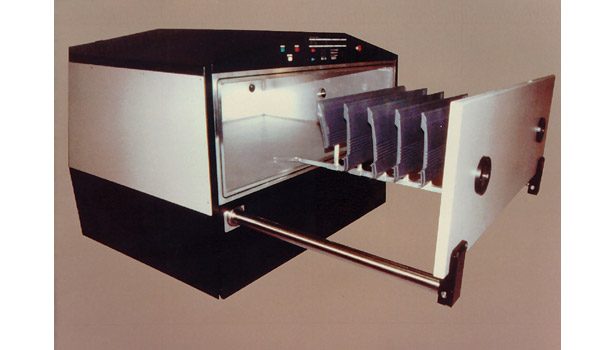

Low-pressure or vacuum plasma describe batch systems that offer some key differences. While they can use clean shop air, most use process gases to achieve a specific functionality or activation of the surface. Because the parts must go into a vacuum chamber, this is not true inline process. Depending on activation cycle time, it is either an offline batch or inline cell process. For small parts such as connectors, the process time per part can be faster than inline treatment processes. The nature of low-pressure plasma also allows treatment of areas beyond line of sight on assemblies like encapsulation housings. Low-pressure plasma is used extensively in electronics and life sciences, where hard-to-bond materials are common.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!