Understanding the Role of Fumed Silica in Adhesives and Sealants Formulations

Fumed silica offers a variety of benefits for adhesives and sealants.

Formulators use particles to enhance the functionality of existing polymer matrices for adhesive and sealant products. Fumed silica is commonly used as a rheology control additive to provide sag resistance, anti-settling of fillers and shear-thinning viscosity. The generic term “fumed silica” defines a range of products with different surface chemistries—from hydrophilic to hydrophobic. These products have differing compatibility to polymer systems, which enable formulators to fine-tune rheology performance.

At the same time, formulators can enhance the viscoelastic response of films or the material properties of cured systems by controlling particle-particle interactions and particle–matrix interfacial adhesion. Such interactions can provide a means of securely incorporating hard materials, which lengthen fracture paths, and dissipate energy at interfacial junctions.1 These properties strengthen films and solids.

In addition to the well-documented benefits in rheology control, fumed silica also enhances the strength of cured adhesives. Following are three examples where fumed silica provides reinforcement of a polymer, resulting in a higher performing adhesive or sealant.

Transparent Silyl-Terminated Polymer

Customers in the do-it-yourself (DIY) market prefer high-clarity transparent silyl-terminated polymer (STP) adhesives and sealants. In Europe, manufacturers of these products have switched to clear packaging to highlight this benefit. Additives such as waxes, clays, and calcium carbonates are commonly used for rheology control and reinforcement of STP adhesives and sealants. The selection of these reinforcing aids typically results in an opaque product because the refractive index of these products does not match the matrix. By contrast, the index of refraction of fumed silica closely matches the transparent polymers commonly used in these products. Fumed silica is widely used to provide reinforcement in transparent STP adhesives and sealants.

Formulators using hydrophilic fumed silicas in moisture curing systems, such as STP or polyurethane, must address premature curing of these systems due to the large water adsorption capacity of hydrophilic silica. Several options are available to solve this challenge, including adding process steps (e.g., pre-drying hydrophilic silica or removing water during compounding via heat and vacuum) or adding additional components (e.g., chemical dryers). A better option is replacing the hydrophilic silica with a hydrophobic silica that can greatly reduce or eliminate the need for these extra process steps.

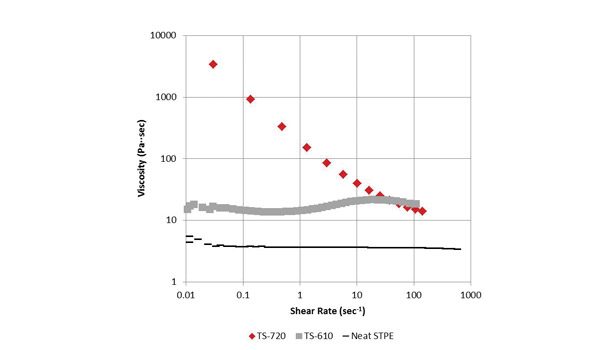

Two hydrophobic fumed silica additives* were compounded in a model formulation consisting of MS Polymer™ SAX 400 silyl-terminated polyether, diisononyl phthalate and an organotin catalyst. The effect of fumed silica surface chemistry on rheology is clearly observed in this system. The less hydrophobic fumed silica additive, with stronger particle-matrix interaction, provides a Newtonian rheology. In contrast, the more hydrophobic fumed silica additive, with weaker particle-matrix and hence stronger particle-particle interaction, provides thixotropic rheology, resulting in a system with a yield stress or sag resistance and viscosity that shear-thins, as shown in Figure 1.

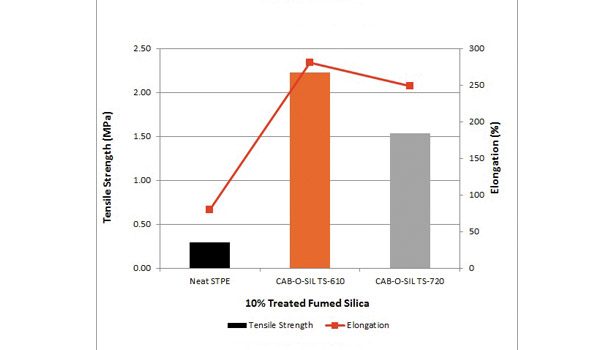

With either of these fumed silicas, the particle-matrix interaction is sufficient to result in increases to the tensile strength of the system (as shown in Figure 2) and a greater than three-time increase in elongation at break. With increased loading of fumed silica, both tensile strength and elongation at break increase but usage at very high loadings is limited by the corresponding increase in viscosity.

*CAB-O-SIL® TS-610 (less hydrophobic) and CAB-O-SIL TS-720 (more hydrophobic)

One-Component Polyurethane

High-surface-area carbon blacks and fumed silica are more efficient on an equal weight basis as a reinforcing agent than other rheology-control additives. Carbon black is used to build viscosity, provide sag resistance, and increase cohesive strength of automotive windshield adhesives. Coated precipitated calcium carbonates (PCCs) are used for rheology control of STP and polyurethane adhesives and sealants. Those PCCs with hydrophobic coatings (e.g., fatty acid or stearic acid) do yield a shear-thinning rheology in polyurethane systems and have the added benefit of providing modest increases in adhesive strength.

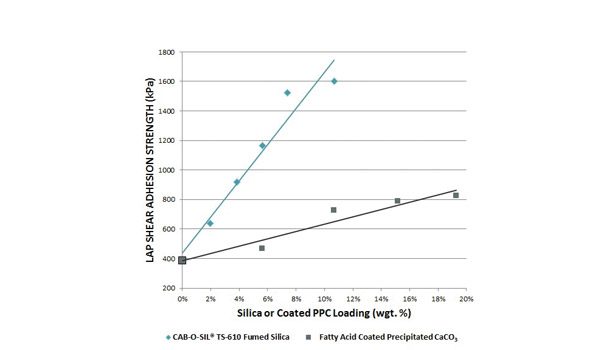

Figure 3 shows the increase of lap shear strength of a moisture-curing, one-component polyurethane adhesive consisting of a polyurethane prepolymer with NCO content < 2%, diisononylphthalate plasticizer, ground calcium carbonate filler, and organotin catalyst, with the addition of either a hydrophobic fumed silica or a coated PCC.

On an equal weight basis, treated fumed silica provides significantly more adhesive strength than the PCC in this system (see Figure 3). Compounding the benefit of lower loading, fumed silica has a lower specific gravity than calcium carbonate and thus contributes far less to adhesive weight, which can be a benefit in applications where adhesive weight is a concern (e.g., automotive lightweighting).

Pressure Sensitives

Fumed silica aggregates are commonly used to improve the processing and performance characteristics of films formed from natural rubber, polychloroprene, acrylates, and many other water-based latex emulsions. These submicron, high-specific-surface-area particles can decrease drying times, mitigate crack formation by modulating the capillary pressure, and enhance the mechanical properties of the final product. Pre-dispersed fumed metal oxides** provide an easy and effective “pour-in” means of incorporating these particles into the adhesive films.

Significant improvements have been observed in cohesive shear strength and thermo-mechanical properties of waterborne pressure-sensitive adhesives (PSAs) due to the incorporation of highly dispersed fumed silica. Adhesive films with fumed silica content ranging from 0 to 15 weight % (dry weight) were formulated from water-based acrylic emulsions designed for PSA applications.

The films were formed by drawing down the emulsions on Mylar backing, and drying the wet films in a ~ 110°C oven for 20-40 minutes. The dry films were cooled at room temperature, backed with waxed release paper, rolled with a 17-lb weight at a controlled rate, and then incubated for 24 hours at room temperature prior to the test. The dry films were 1-1.3 micron dry film thickness (DFT).

Film shear strength was measured as a function of shear force (1.1 to 4.4 psi) and temperature (room temperature to 100°C) in a two-bank, eight-position shear oven (see Figure 4). Four or more adhesive samples from a given draw down were typically evaluated, yielding relative standard deviations in time to failure of ~ 15% or less. The film shear strength enhancement was calculated as the mean time to failure of the film normalized by the mean time to failure of the films without particle reinforcement.

Shear measurements show significant increases in shear strength enhancement with fumed silica loading as low as a few weight %. For example, at 4 weight % in the room temperature evaluation, the adhesive shear strength is increased 8-20 times, depending on shear force. At higher weight % (e.g., 8-15%) and higher temperatures (e.g., 100°C), the shear strength enhancement as a result of fumed silica addition is even more striking. Adhesive shear strength typically increases more than a thousand-fold compared to the films without particle reinforcement. The chemical bond formation in these adhesive films caused by the addition of fumed silica dispersions is currently being investigated, as this level of enhancement was unexpected. Regardless of the source of the shear strength enhancement, the increase in film cohesive strength is significant.

The peel strength of the PSA films with and without fumed silica reinforcement was also evaluated (with a ChemInstruments Adhesion/Release AR-1000 peel tester). A 7-lb weight was used to roll 10 x 1-in. adhesive strips onto a stainless steel adherent at a controlled rate; the time lapse between the end of rolling and the peel test was 1 min. The reduction in peel strength as a result of fumed silica reinforcement is fairly modest: over a range of 0 to 4 weight % fumed silica, the peel strength deceases linearly to ~ 75% of its initial value. Between 4 and 8 weight % fumed silica, no further reduction in peel strength is observed.

No tackifiers were used in the PSA data discussed here. For products requiring high adhesion via tackifier addition, reinforcement via fumed silica has been shown to more than compensate for the shear strength loss caused by tackifier addition (e.g., Tacolyn 3509). The 20-40% loss in shear strength caused by common tackifier levels is easily recovered via 2-4 weight % fumed silica reinforcement.

**such as CAB-O-SPERSE® dispersions

The Right Balance

Balancing the strength of particle-matrix and particle-particle interactions by selection of the appropriate surface chemistry of fumed silica allows formulators to achieve performance targets for the rheology in the uncured state and reinforcement or strength of the cured adhesive or sealant. Fumed silicas are multi-functional particles providing performance—along with unexpected benefits in reinforcement—in a range of adhesives.

For more information, call (800) 462-2313, email performance.na@cabotcorp.com or visit www.cabotcorp.com.

Reference

1. Akcora, et. al., Nature Materials, 2009, 8 (4) 354-359.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!