Environmentally Sound Pressure-Sensitive Adhesive Tape Manufacturing

RTM certification acknowledges and raises the visibility of PSTC member companies that invest in being responsible tape manufacturers.

In an uncertain and changing world, the Pressure Sensitive Tape Council’s (PSTC) Responsible Tape Manufacturer (RTM) program is helping member companies that manufacture pressure-sensitive adhesive (PSA) tape products to demonstrate that their products are made in a responsible manner with regard to the environment, people, facilities, and quality systems. Introduced in 2010, the third-party audited system is a PSTC membership requirement. PSTC RTM certification acknowledges and raises the visibility of PSTC member tape companies that invest in being responsible manufacturers.

Designed to be uniquely comprehensive, the program recognizes good manufacturing practices as an integral part of the value that PSTC member tape companies bring to their customers. RTM certification delivers quantifiable differentiation between RTM-certified tape companies and all other tape producers. The program identifies PSTC member tape producers that have sustainable best practices in environmental, manufacturing safety, and health and quality control standards.

Each member company providing tape products is expected to use the official PSTC RTM program document and RTM audit checklist to obtain responses from all applicable manufacturing facilities for tape products sold in the U.S., including:

• Company facilities located in the U.S.

• Company facilities located outside the U.S.

• Contract facilities that manufacture company-purchased jumbo materials and/or purchased finished goods in the U.S.

• Contract facilities that manufacture company-purchased jumbo materials and/or purchased finished goods outside of the U.S.

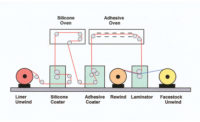

Manufacturing activities include the mixing of adhesives and other coatings that does not typically result in a rise in temperature or pressure, as well as associated coating operations. Polymerization and chemical reaction processes (i.e., processes that typically result in a rise in temperature or pressure), purchased raw materials (e.g., adhesives, solvents, paper, film, cores, etc.), slitting, and packaging are not in the scope of RTM. Similarly, the production of labels is not in the scope of RTM.

The foundation of the RTM program is an RTM Program Document, which brings together relevant regulations, standards, and practices that PSA tape companies must follow for U.S. government and ISO compliance. This single resource captures these standards and serves as a management review reference for associated processes and finished products. These standards represent best business practices with which PSTC member tape companies should already be complying.

Wayne Helton, PSTC Board past chair, emphasized the significance of the RTM program, noting that RTM-certified companies are raising the bar for those companies electing not to take part in the certification process. Simply, RTM certification makes buying decisions uncomplicated. Those purchasing tape from RTM-certified companies can be assured of the highest quality products manufactured according to best sustainable environmental control practices and high standards for the treatment of people and the management of the facilities in which they work.

“When customers shop the world, it is difficult to ascertain how product is being manufactured,” Helton says. “But our RTM process helps members understand quality systems, environmental practices, and, perhaps most importantly, how a company treats and manages its people. PSTC members think of themselves as stewards of the environment and of our employees, and that this is the right way to do business.”

Certification Process

Starting in June 2012, PSTC member tape companies collected and delivered facility audit checklists to/from each of their applicable manufacturing facilities. As part of the process, it was expected that the facilities also provide supporting documentation to the PSTC member tape company to substantiate their individual audit scores.

Passing RTM qualifications requires a minimum total audit score of 70%. If any total facility score was less than 70%, the failing facility needed to submit a corrective action plan to the PSTC member tape company committing to make whatever changes were deemed necessary to achieve a minimum total audit score of 70% by April 2014.

In September 2013, PSTC member tape companies were required to submit their company’s Declaration of Compliance to the RTM program to the PSTC. Beginning in October 2013, each RTM self-certified PSTC member company was audited by a PSTC-appointed independent auditor.

Once all conditions were met (i.e., each tape manufacturing facility under the company’s direction has either a passing total audit score of 70% or higher or has submitted a legitimate corrective action plan showing the facility can achieve a passing total audit score by April 2014), the PSTC then provided the PSTC member tape company the RTM logo and promotional tools for the company’s use, which designates them as RTM certified.

As of October 3, the following PSTC member companies have completed the rigorous certification process:

- 3M

- Adchem Corp.

- Adhesive Applications Inc.

- Adhesives Research Inc.

- American Biltrite Inc.

- Avery Dennison Corp.

- Berry Plastics Corp.

- Cantech

- Coating and Converting Technologies Inc.

- Essentra Specialty Tapes Inc.

- FLEXcon Industrial LLC

- Great Lakes Coating and Laminating Inc.

- Intertape Polymer Group Inc.

- Lamart Corp.

- MACtac North America

- main tape

- Navilux S.A. de C.V.

- Shurtape Technologies LLC

- Syntac Coated Products LLC

- TaraTape

- tesa tape inc.

For additional information, call (630) 544-5048, email info@pstc.org or visit www.pstc.org/RTM.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!