A Closer Look at Planetary Mixers for Adhesives and Sealants Production

Double planetary mixers are standard workhorses that continue to evolve with the changing needs of the adhesives and sealants industry.

Classic double planetary rectangular blades. A Teflon scraper is attached to the bottom crossbar of one blade. The mixer is supplied with a rotating thermoprobe for high-accuracy temperature monitoring.

Sanitary double planetary mixer with highviscosity (HV) blades, designed for medicalgrade adhesives. A discharge system is used to press out the finished product, which would otherwise not flow readily by gravity alone.

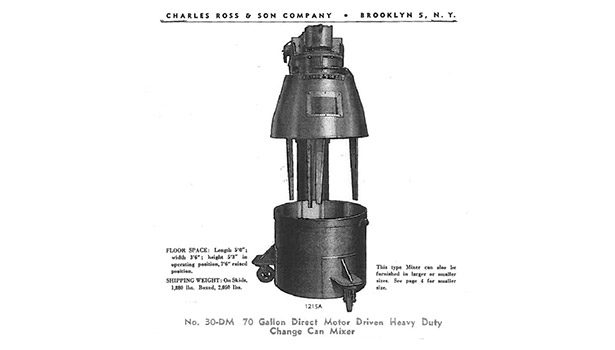

When the first change-can double planetary mixer was introduced in the early 1940s by Charles Ross and Son Company, it quickly became a popular machine for batching heavy paste paints. It had two sets of prong-like stirrers that rotated on individual axes while revolving around the vessel interior. All the gearing and other moving parts were enclosed in cast-iron housings and operated in a continuous oil bath. The vessel was fully covered during mixing, but the operator could see the internals from a lamp-lit inspection window. When the batch was complete, a hydraulic lift raised the driving components and stirrers from the mix can. As the finished product was discharged, another vessel could be placed under the mixer to start a new batch.

This was a revolutionary design that improved upon pony-style mixers that were widely being used at that time. The pony mixer’s agitator comprised vertical blades or fingers oriented off-center of the vessel. The blades rotated from a fixed central axis while the vessel (installed on a turntable) turned in the opposite direction of the agitator. The pony mixer was an open system, making it prone to dusting and cross-contamination. The double planetary mixer eliminated these issues and improved operator safety.

Soon after, the double planetary mixer became a familiar machine outside of the coatings industry. Its ability to turnover viscous, sticky or putty-like materials with great efficiency offered obvious processing benefits to adhesive and sealant manufacturers. Today, double planetary mixers—and other planetary-style mixing equipment subsequently developed—are standard workhorses that continue to evolve with the changing needs of the industry.

Improved Blade Design

As their name implies, double planetary mixers have two identical blades that move in a planetary motion, rotating on their own axes as they orbit on a common axis. In only 36 revolutions around the vessel, the blades pass through every point in the product zone, physically contacting the entire batch.

Double planetary mixers are equipped with a few different styles of agitators; for many decades, however, the most preferred was the rectangular paddle-shaped blade. With a very strong construction, the vertical flights and horizontal lower crossbar of each rectangular blade are sloped to generate both radial and axial flow. Materials around the periphery are reincorporated into the batch by the close-tolerance planetary stirring action. In some applications where the product tends to form a film on the vessel surfaces, sidewall and/or bottom scrapers are installed to facilitate a more effective exchange of materials.

Moving at relatively low speeds, the two planetary blades provide thorough but gentle agitation to low- and medium-viscosity applications. Shear-sensitive adhesive gels and syntactic foam sealants benefit from this delicate folding and blending mechanism. When mixing higher viscosity products up to around 2 million centipoise (cP), however, the blades impart much greater shear—in this regime, they knead the batch with sufficient force, smoothing out its consistency and breaking up any dry solid agglomerates. For this reason, it is common for operators to artificially raise batch viscosity by withholding some portion of the liquid binder or solvent to accelerate dispersion. Once all solids are mixed in and the desired level of dispersion is achieved, the batch is then carefully let down to the final viscosity.

Gravity and centrifugal forces keep product within the mixing zone. At elevated viscosities, however, certain products tend to climb up the vertical flights of the rectangular stirrer. When this happens, some batch materials basically spill out of the vessel and get hung up on the mixer cover or near the gearbox where the rotating blades cannot reintroduce them back to the mixing zone. Product migration reduces mixing efficiency and necessitates frequent pauses to manually scrape down all problem areas.

To overcome this issue, a new planetary stirrer design was developed: high-viscosity (HV) blades (U.S. Patent No. 6,652,137). Featuring a precisely angled helical contour, HV blades generate a forward and downward mixing action, keeping product within the vessel at all times and preventing the climbing problem sometimes experienced with traditional rectangular stirrers. In addition, the blades enable the double planetary mixer to handle more viscous products (as high as approximately 6 million cP), including applications that previously required a more expensive horizontal sigma blade kneader. The rotating helical stirrers pass each other in a slicing motion, which more evenly distributes the resistance of thick, non-flowable materials compared to the vertical flights of rectangular blades. The absence of horizontal crossbars also allows the HV blades to be lifted very cleanly and easily out of a viscous batch without any large portions of product clinging to them. Due to the previously-mentioned advantages, HV blades have been the agitator of choice in the majority of Ross double planetary mixers built since the early 2000s.

Enhanced Sealing Arrangements

Aside from blade design, several improvements to the double planetary mixer have emerged over the years in response to the needs of its most avid and demanding users, many of whom are adhesive and sealant manufacturers. For instance, a number of gearbox and sealing options are available that further minimize contamination to the product and to the machine.

Stirrer shafts are traditionally sealed by PTFE lip seals. For tighter protection against any grease that may tend to escape the gearbox, double lip seals or mechanical seals may be supplied. Magnetic seals may also be used on the shafts when aggressive solvents are present.

In addition, the gearbox can include a dust shield or liquid seal. Mounted under the gearbox, a dust shield prevents product dust and splash from getting up into the gearbox, enabling easier cleaning between batches. A liquid seal, on the other hand, is a barrier that protects the gearbox drive assembly from a wider range of contaminants, such as dusts, splashes and even evaporated solvents. For sanitary and medical-grade applications, the gearbox may be sealed and purged to completely prevent entry of vapors and airborne particles.

Planetary Dispersers

As explained, double planetary mixers rely on elevated viscosity to impart considerable shear. Formulations that require shear but do not reach high enough viscosities are better prepared in a planetary disperser equipped with both low- and high-speed agitators. Instead of two identical stirrers, it has one planetary blade and a high-speed shaft with one or more saw-tooth disperser blades. The disperser turns on its own axis at tip speeds in the range of 4,000 ft/min and quickly incorporates dry ingredients into the batch.

The slower planetary blade continuously sweeps the vessel walls, as well as the vessel bottom, and carries material toward the disperser. It also serves to dissipate heat created by the saw-tooth blade(s) and promote thermal uniformity throughout the batch. Both agitators of the planetary disperser are independently controlled, so flow patterns and shear rates are easily fine-tuned as the product undergoes changes in rheology and other physical characteristics throughout the mixing cycle.

Planetary Dual Dispersers

If you take the classic double planetary mixer with two identical blades and add two high-speed shafts with saw-tooth blades, you get a planetary dual disperser for even greater shear intensity and more rapid dispersion of dry powders into a viscous batch. With this robust system, solid additions can be made in larger quantities and shorter intervals. Each disperser shaft is typically equipped with at least two saw-tooth blades so that agglomerates anywhere in the batch are disintegrated faster and turnover is extremely efficient even if the material is particularly dense or sticky.

Planetary dual dispersers also offer a unique processing flexibility—both disperser shafts are removable, allowing the mixer to be operated as a regular double planetary mixer. This feature is beneficial when a single mixer is used for batching a range of products, not all of which require high-speed mixing.

The Value of Testing

In addition to planetary mixers, multi-shaft mixers, kneaders and extruders cater to the processing of high-viscosity adhesives and sealants. The evolution of all these different technologies over the years has resulted in great overlap in terms of use and function. For this reason, adhesive and sealant manufacturers should consider using the free-of-charge testing services offered by many mixer manufacturers. This allows specific formulations to be batched in several appropriate mixer types, with comparisons of cycle times, ease of cleaning, completeness of discharge, heating requirements, energy costs, and other metrics.

Once the best technology is determined, the mixing procedure can be further refined by performing additional tests on a rental unit. For a fraction of the capital cost, manufacturers can confirm horsepower requirements, experiment with different methods and order of ingredient addition, or jumpstart production and operator training.

For additional information, contact the author at (631) 234-0500, ext. 249, or cbanaszek@mixers.com.

Reference

1. Ross, C.K., Future Through Retrospect, Thesis, Yale University, U.S., 1947.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!