Two-Component Dispensing Solution for Adhesives and Sealants

Upgrading production to two-component dispensing systems can offer multiple benefits.

With the continuous improvement of current metering and dispensing technology, two-component equipment proportioning and mixing precision can reach ±1%. Manufacturers that previously worried about the unstable performance of two-component dispensing equipment are now increasingly upgrading their production from single- to two-component in order to achieve the multiple benefits now offered by two-component adhesives and sealants technology, including: fast curing, chemical reaction curing (cures simultaneously from inside to outside), and better bonding strength and seal effects.

Two-component dispensing systems are widely used in the automotive, engineering machinery, appliances, LED, solar energy and other industries. The systems consist of a material transfer unit, metering unit, pressure stabilization unit and dispensing valve. In addition, automatic dispensing can be realized with the addition of an industrial robot and ¾ axle sliding table.

Material Handling

The most commonly used packaging for adhesives and sealants are 5- and 55-gal containers. Pneumatic piston pumps with follower plates are used to transfer the adhesives and sealants from containers to the metering unit. These pumps can easily handle fluids up to 1 million cPs, and the outlet pressure can reach more than 400 Bar. For corrosive materials, such as acrylic ester, a stainless steel pump body and compatible packing are needed.

Improvements in air motor technology have shortened the changeover time of the piston pump to less than 0.1 seconds, which can significantly reduce the fluid pressure pulsation. However, the pressure pulsation still brings impact to the dispensing system and further affects the measuring accuracy. Therefore, a material pressure regulator is normally placed before the metering equipment to stabilize the pressure at the appropriate level.

Metering Principle

Cylinders and gear pumps are the most commonly used metering devices. (For higher requirements, a flow meter can be incorporated to improve metering accuracy.) These metering methods each have different strengths. Gear pumps are generally the best choice for most conditions. However, material containing high abrasive fillers will seriously affect the metering precision and service life of a gear pump. These abrasive fillers quickly wear the pump gear and further cause internal leakage, resulting in reduced metering accuracy and undesired final coating defects. As a result, the cylinder should be used to meter abrasive materials. The surface of the plunger and inner surface of the cylinder are highly polished; high hardness stainless steel materials and upgraded packing are also used to further improve wear resistance.

The metering device (whether gear pump or cylinder) is connected to a servo motor. The extrusion amount of these positive displacement metering devices can be controlled through the motor speed and angle. The gear pump’s volume and cylinder diameter are determined by the various flow and mixing ratio requirements of the specific application.

Pressure Stabilization System

Pressure instability is a common cause of inaccurate metering. In a gear pump metering system, if the pressure difference between the input and output of the pump is too large, it will seriously affect the service life of the gear pump. The system’s pressure can be stabilized through the real-time monitoring of fluid pressure in the pipeline, along with any necessary compensation by the pressure regulator.

Mixing Method

Dynamic mixing and static mixing are commonly used with two-component equipment. Dynamic mixing is driven by an electric motor; the two components are extruded into the mixing tube for high-speed agitation and then dispensing. This kind of mixing method can realize an excellent mixing effect and is suitable for two-component materials that have a large viscosity gap between the two components or have a high mixing ratio. Disadvantages include equipment complexity and necessary cleanup between uses.

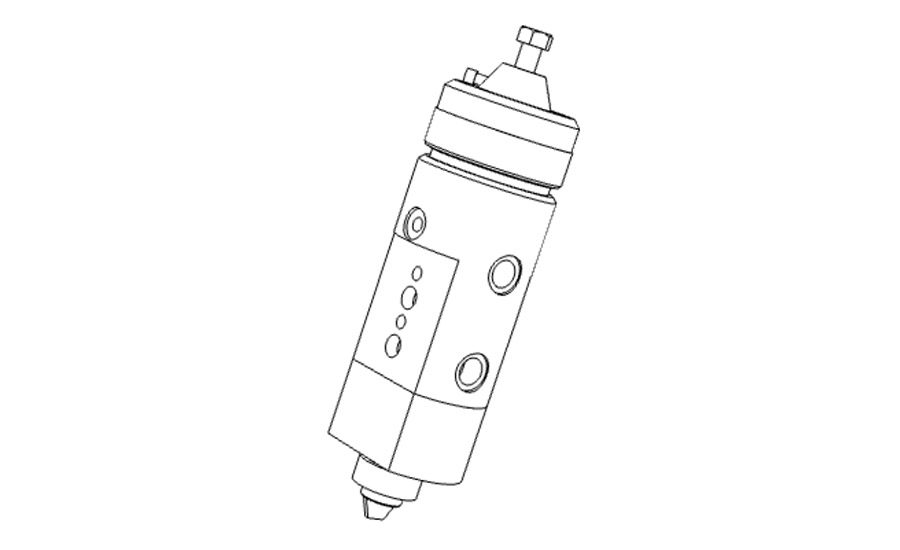

Static mixing usually incorporates a two-component dispensing valve and a static mixing tube. Two components are extruded into the mixing tube through their respective channels located in the dispensing valve. In order to realize an even and automatic mixing process, continuous cutting and restructuring are completed through a series of mutually perpendicular levorotatory and dextrorotary blades located in the mixing tube. The two-component dispensing valve is generally a snuff-back type, which eliminates dripping and provides a faster shut-off. In order to avoid contamination and curing, the two components do not contact each other before they enter the mixing tube.

The low-cost static mixing tube is easy to replace. Changing a new mixing tube is the only process before each use. The wide applicable range and good mixing effect of the static mixing tube can help manufacturers save labor, increase production efficiency and lower production costs, making static mixing a viable method in today’s business environment.

For additional information, contact the author at wenlong.luo@irco.com or visit www.arozone.com.

Author’s note: ARO was founded in 1930 and joined Ingersoll Rand in 1990. It is a brand of Ingersoll Rand to provide fluid products.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!