Henkel Opens Composite Test Center

Henkel recently announced it has opened a composite lab in Heidelberg, Germany.

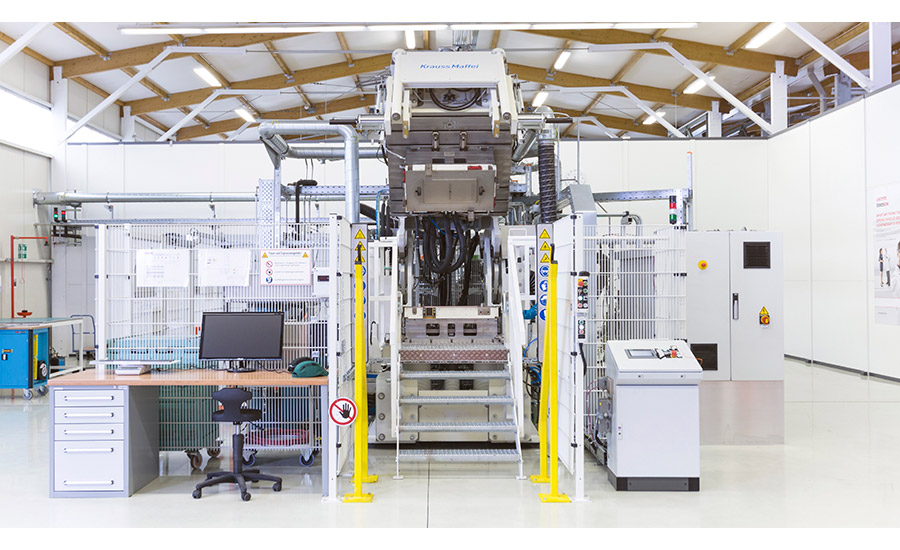

Henkel recently announced it has opened a composite lab in Heidelberg, Germany. The test facility reportedly allows automotive customers to partner with Henkel to develop and test composite parts and to figure out the best production process conditions to make their ideas market-ready.

Automotive OEMs and Tier-1s are constantly seeking cost-effective processes suitable for production of more than 10,000 parts per year. They want custom-formulated, fast-curing resins for use in short production cycles. Henkel reportedly opened its composite lab to allow customers to complete trials using high-pressure resin transfer molding (HP-RTM) equipment. The HP-RTM machine includes a 380-ton press and injection equipment for polyurethanes and epoxy materials.

For more information, visit www.composite-lab.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!