Henkel to Develop Solutions for 3D Printing

Henkel recently announced plans to offer novel light-cure resins for use in SLA/DLP printing.

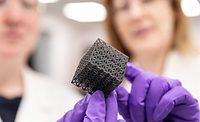

Henkel recently announced plans to offer novel light-cure resins for use in stereolithography (SLA)/ digital light processing (DLP) printing. The first of these new materials reportedly will be commercialized in 2017. Henkel hot-melt adhesives also have been used in additive manufacturing for functional applications such as furniture and elements for buildings. The company is reportedly focusing development in this area to provide novel filament and powder materials for us in selective laser sintering (SLS) and fused deposition modeling (FDM) 3D printers.

“Thanks to our broad material portfolio and our large customer base across different industries, we have the access and ability to enable 3D printed solutions for all kinds of functional applications,” said Mike Olosky, corporate senior vice president and global head of innovation and new business development. “We believe strongly in the future of additive manufacturing and expect that its full potential will come by identifying the right customer application and focusing the right materials, with the right printing process and leveraging the right software.”

Henkel has also partnered with DUS Architects, a Dutch design and architecture startup, who initiated the canal house project in Amsterdam in 2014. With the help of additive manufacturing, a house façade and interior walls, made up of 42 components, reportedly will be printed and constructed by 2017. Earlier this year, DUS designed the façade of a mobile conference building in Amsterdam. The individual elements were manufactured using Henkel hot-melt adhesives based on sustainable raw materials, and then injected with concrete.

For more information, visit www.henkel.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!