Case Study

Improving Polyurethane Coatings for Water Infrastructure

A new polyol can extend the life of company equipment and facilities while meeting stringent federal containment regulations.

America’s infrastructure GPA stands at a D+, with an estimated $3.6 trillion of work needed by 2020 to repair the country’s out-of-date structures, bridges, roads, etc.1 Part of these issues lie within public parks and recreation, which are being used by a reported 140 million Americans on a daily basis.

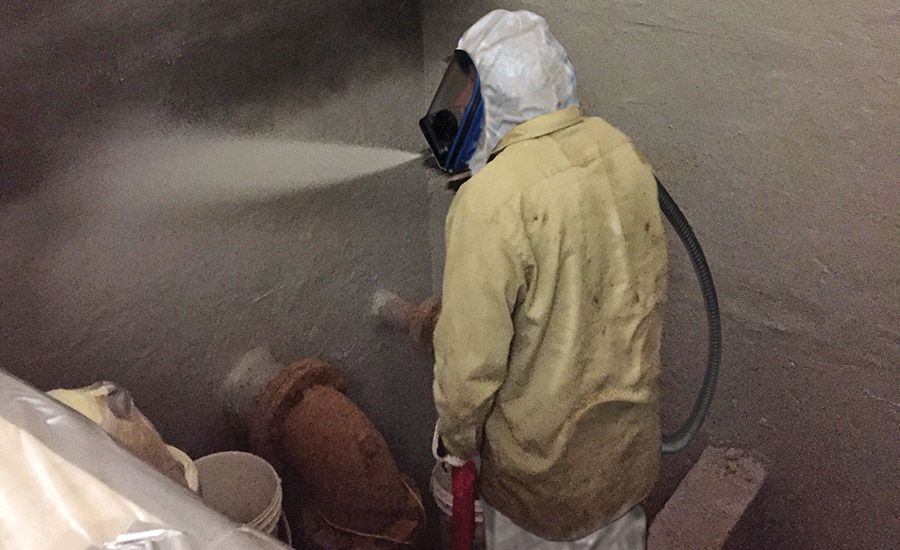

Recently, the city of Houston attempted to repair subgrade overflow basins for its public pools to provide better assets to the community. These basins needed to be coated to protect from potential corrosion and to prevent water leaks. After multiple failed attempts to find a reliable coating, the city turned to Evergreen National, an authorized Rhino Linings® applicator, to provide a long-term waterproofing solution that would truly and safely seal and prevent leaks for years to come.

Finding a durable polyurethane product, which also matched the city’s initiative to reduce its carbon footprint, was a challenge Evergreen National and Rhino Linings to create a polyurethane solution knew they could meet by partnering with The Dow Chemical Co. Polyurethane technology is well-established in industrial and infrastructure markets due to its workability, flexibility, mechanical properties, and good adhesion to a variety of substrates.

The new product that resulted from the partnership between Dow and Rhino Linings combined Dow’s VORAPEL™ hydrophobic polyol with other materials to create Rhino Linings’ HiChem™ 11-70. The solution is reportedly ideal for businesses looking to extend the life of company equipment and facilities while meeting stringent federal containment regulations concerning waste management and the safe storage of hazardous materials. This project found that hydrophobic elastomeric coatings can replace epoxy systems in maintenance jobs where chemical resistance, fast return to service and high damage tolerance is critical.

“Our partnership with Dow has led to the development of our most chemically resistant product to date,” said Pierre Gagnon, president and CEO of Rhino Linings. “HiChem 11-70 showcases both Rhino Lining’s polyurea expertise and Dow’s material science knowledge. We expect this high-quality and chemically resistant product to be a best seller.”

Rhino Linings sought a standout Dow polyol to develop a 100% solids material that minimizes volatility and offgassing in all projects while also providing rapid return to service with the VORAPEL family of polyols and prepolymers. The maintenance of the coatings on these types of assets also doesn’t typically offer a rapid return to service, but given the need to make up for lost time, Dow’s solution delivered added value.

While previous polyureas were known to cure rapidly, they didn’t have the chemical resistance of epoxy coatings until Dow developed the VORAPEL solution. This new system delivers coatings capable of meeting the demanding needs of industrial settings for increased moisture and chemical resistance while providing formulators with a low-viscosity solution. In addition to chemical and corrosion resistance, the protective lining cures quickly, ensuring businesses experience little-to-no downtime and, in some cases, may return to service in less than 24 hours.

“Rhino Linings and Dow delivered exactly what we were looking for to meet requirements for the city’s environmental standards,” stated Steve Doxey, vice president of business development for Evergreen National. “HiChem was even better than expected as it has high tensile strength and a dense, impermeable chemical structure perfect for preventing the underground leaks Houston had experienced with previous products.”

After the initial application, Houston was hit with record high rainfall and experienced zero failures with the HiChem 11-70 coating. The city of Houston was thrilled with the Rhino/Dow solution after seeing this success in extenuating circumstances, and the companies are spec’d for all future jobs in Houston.

For more information, visit www.dowpolyurethanes.com or www.rhinolinings.com.

Reference

1. ASCE, America’s Infrastructure Report Card, www.infrastructurereportcard.org/a/#p/grade-sheet/gpa, 2013.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!