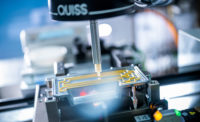

SCHEUGENPFLUG AG: Dispensing System

The A220 basic dispensing system reportedly offers a new entry-level solution for the bubble-free feed of highly viscous and non-abrasive dispensing media.

The functions of the A220 are oriented toward a stable and process reliable material feed. Docking the pump to the 20-l standard container is handled manually via a two-hand circuit and can be monitored with a visual check via a pressure gauge. The patented vacuum follower plate offers a clean and bubble-free docking process. It is made of polypropylene (PP) and is disposed of along with the empty container after the feeding process, preventing the introduction of residual material into the new drum. The integrated reciprocating pump reportedly provides continuous material supply, as material is fed during both the upward and downward stroke.

The A220 features a filling level control unit and an electro-pneumatic pressure control unit. Both control units reportedly contribute to the high process reliability of the new feeding system. The system is operated via the Scheugenpflug SCP200 controller, which can not only facilitate monitoring, maintenance and analysis tasks, but may also ensure an economical and fault-free feeding process.

For more information, visit www.scheugenpflug-usa.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!