DOW AUTOMOTIVE SYSTEMS: Structural Adhesives

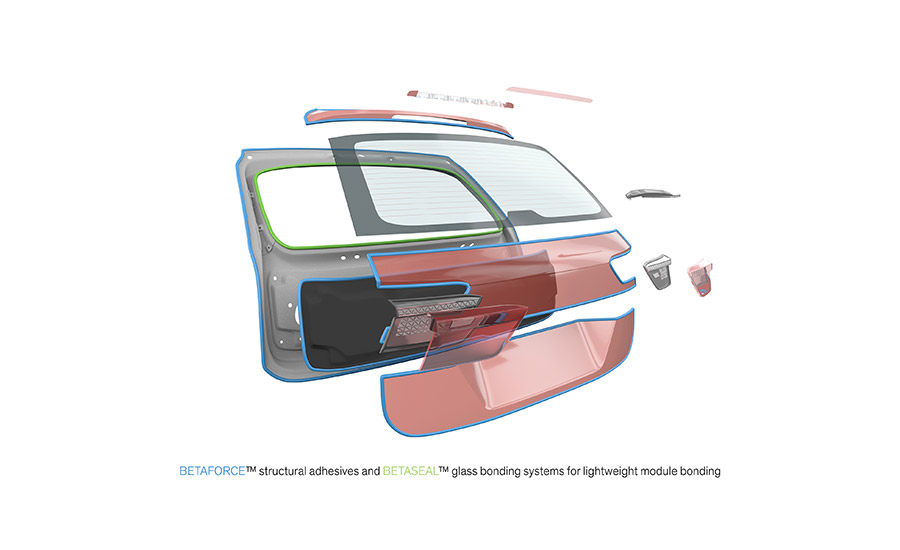

This company is reportedly leveraging its existing structural adhesives portfolio as well as its development expertise to offer BETAFORCE™, BETAMATE™ and BETASEAL™ solutions that enhance lightweight module construction.

“For those tiers and OEMs adopting mixed-material design, 3-10kg weight savings per module have already been realized,” said Christophe Van Herreweghe, marketing manager, body and exteriors. “Use of Dow structural adhesives helps enable those targets and further enhances the module through the ability to bond dissimilar substrates, reduce welding and mechanical fasteners, seal against corrosion for better durability and increase strength and stiffness for crash worthiness and enhanced customer driving experience.”

The adhesives are reportedly developed with rapid-cure characteristics that process well in mass production manufacturing environments. Primerless-to-plastic formulations help remove VOCs from assembly operations, and new multifunctional adhesives are in development.

For more information, visit www.dowautomotive.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!