Stick and Stay Stuck: Optimizing Performance for Pressure-Sensitive Adhesives

It is vital to use the correct pressure-sensitive adhesive for the specific material and environment.

In general, the more textured a substrate is, the more difficult it is to bond to.

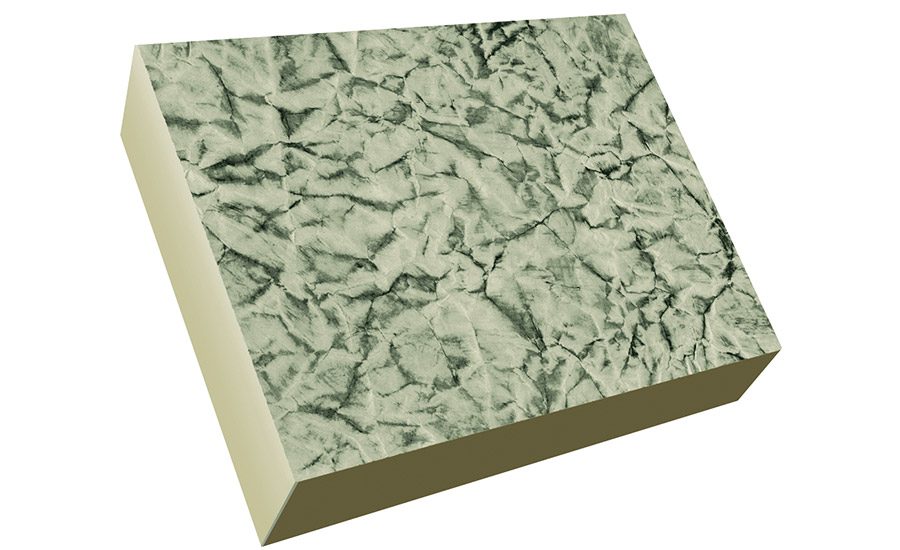

Examples of substrates with challenging surface areas include clothing textiles (a) and open-cell polyurethane foam (b).

Production problems…we’ve all been there. Consider this: A new type of plastic was selected for an automotive headlamp component. Nothing else has changed in the manufacturing process—but it should have been. Now the water seal, an ethylene propylene diene terpolymer (EPDM) foam die cut laminated with pressure-sensitive adhesive, is not bonding to the new plastic and is simply falling off.

In another scenario, the materials for a new building insulation bonded perfectly for the first six months of use, and the new product was a hit. Then summer came along, temperatures began to rise, and the insulation materials started to delaminate and fall apart.

In every situation, two main considerations—the materials being bonded and the environment of the application—can make all the difference in pressure-sensitive adhesive success or failure. When selecting adhesives for certain materials, you must consider the surface energy and texture of those materials. You must also consider the environmental conditions (e.g., temperature and humidity) that these materials will be subjected to.

Specifying the proper adhesives and working with converters and adhesive manufacturers is a key element in designing any new product or revising an existing one. Knowing the basic properties of an adhesive is a start. Factors beyond that must be also considered, and the best time to do that is early in the design stage.

Surface Energy

A substrate’s surface energy (the way a surface can be measured to indicate how something will bond to it) has a direct impact on an adhesive’s ability to bond to the substrate. Low-surface-energy (LSE) materials tend to present a larger challenge than high-surface-energy (HSE) materials.

For example, most metals are HSE materials. Plastics, however, can be both. This includes HSE plastics such as acrylonitrile butadiene styrene (ABS) and polycarbonate (PC), as well as LSE substrates like polyethylene (PE) and polypropylene (PP).

Selecting the wrong adhesive can result in weak bonds that lack the strength to effectively adhere to materials, which may cause materials to lift off substrates or completely separate. Rubber-based adhesives tend to bond well to LSE surfaces, as do acrylic-based adhesives modified with tackifiers, which “soften” the adhesive for higher flow (thus higher tack). Such solutions are well-suited for automotive applications, where many plastic applications present themselves.

Surface Texture

In general, the more textured a substrate is, the more difficult it is to bond to. If an application employs an adhesive that doesn’t flow enough or is too thin, it won’t bond to enough surface area. Such applications typically require a tackier adhesive with a higher coat weight. The tackier the adhesive, the more it will flow and fill the gaps in foams and heavily textured fibrous materials.

A simple example is that of clothing textile materials. But it can also be as complex as open-cell polyurethane foam bonding for use in acoustical absorption or gasketing in a wide range of end user segments such as automotive, white goods, or general industrial.

Environment

Now that the material factors have been considered, the environment of the application must be assessed. The first and main concern should be temperature. Temperatures can vary from application to application, and this affects whether an adhesive succeeds or fails. A good rule of thumb for temperature resistance is that rubber-based adhesives will work fine for temperatures below 150˚F, while acrylic-based adhesives can resist temperatures around 350˚F. Applications in higher temperature ranges will often need testing or previous data to help support a proper recommendation.

Other environmental conditions—including humidity; indoor/outdoor use; exposure to solvents, chemicals, or fuels; and direct or indirect UV exposure—all come into play as well. In general, acrylic-based adhesives have much better resistance to these types of conditions when compared to rubber-based adhesives. As with temperature, technical support is recommended if the application has a high exposure to these conditions.

Sticking to the Plan

While no single adhesive is right for every application, two questions should be asked in the design phase when considering an adhesive: what materials are being bonded, and what environments will be faced? This exploration should be done early in the design phase, not when a die-cut part is about to go into production.

The good news is that a design engineer has the resources of the tape converter and tape manufacturer when making these selections. Consulting these experts can help ensure the parts being stuck together will stay stuck—and prevent you from getting into a sticky situation.

For more information, contact the author at scott.krusinski@averydennison.com or visit www.tapes.averydennison.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!