Advancing Adhesives

Advances Toward Non-Yellowing Optically Clear Silane-Modified Polymer-Based Adhesive Formulations

Using hydrophobic surface-treated fumed silica in combination with a novel non-yellowing amino-functional silane adhesion promoter leads to an optically clear silane-modified polymer-based adhesive system with superior color stability.

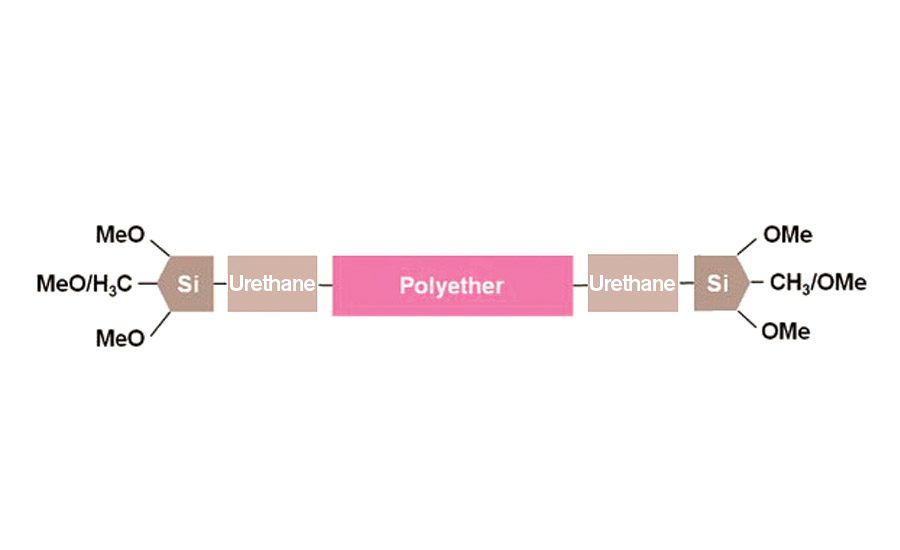

Figure 1. Structure of the silane-terminated polyurethane (STPU) used in this study.

Figure 2. Cured 2-mm dry thickness films of the formulations made with different fumed silicas: (a) no silica, (b) 10% AEROSIL® R 974, (c) 10% AEROSIL® R 202, (d) 10% AEROSIL® R 106, (e) 20% AEROSIL® R 8200, and (f) 20% SIPERNAT® D 13.

Figure 3. Transmittance of the AEROSIL® fumed silicas as measured on a Turbiscan.

Figure 4. Optically clear and colorless formulation made with the STPU, hydrophobic surface-modified fumed silica AEROSIL® R 106, and specialty amino-functional silane Dynasylan® VPS 1142. Left: uncured formulation; right: cured draw down (thickness 2 mil).

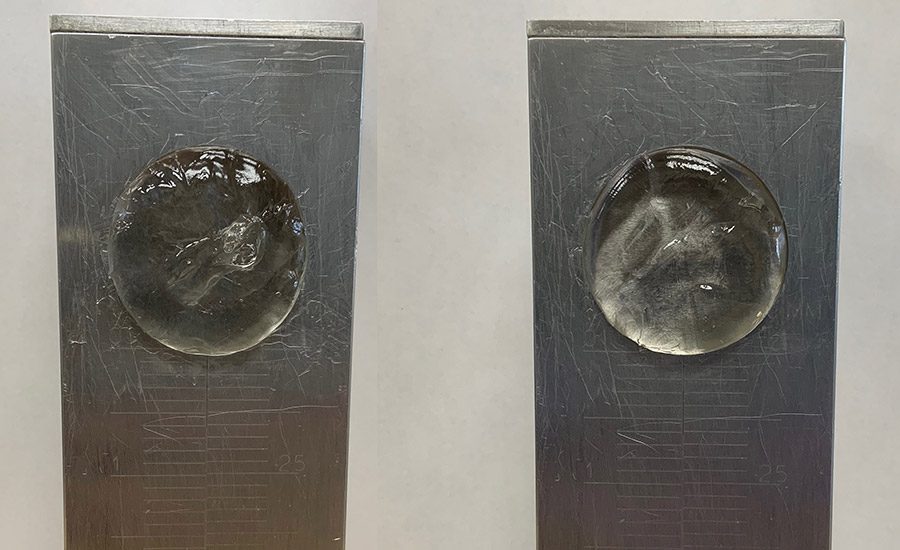

Figure 5. Boeing slump resistance test of the formulation made with the hydrophobic surface-modified fumed silica AEROSIL® R 106 and the specialty amino-functional silane Dynasylan® VPS 1142, after 1 day (left) and 7 days (right).

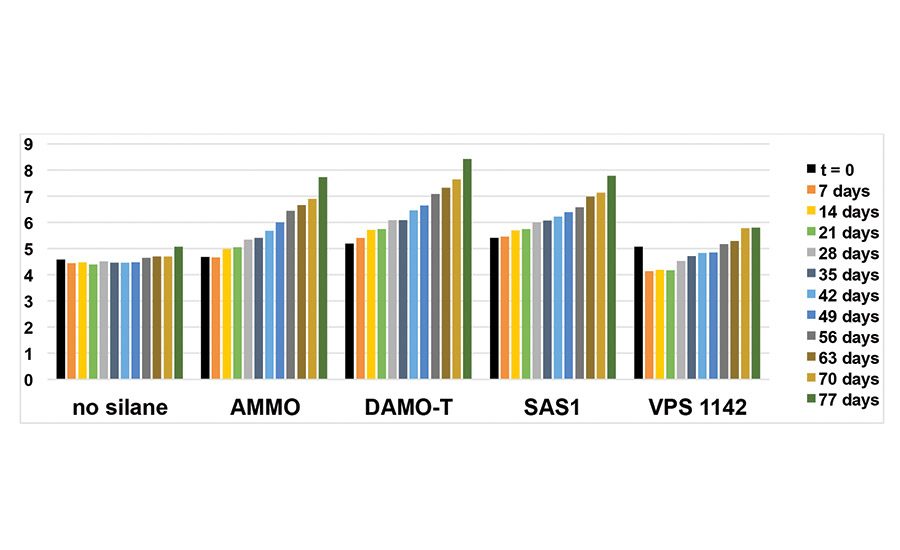

Figure 6. Yellowness (b value) as measured using a colorimeter of formulations containing different amino-functional silanes that were aged at 50°C over 77 days. Without any amino-functional silanes, the formulation does not properly cure. The Dynasylan® VPS 1142 shows the best color stability (Δb < 2) of all the amino-functional silanes tested.

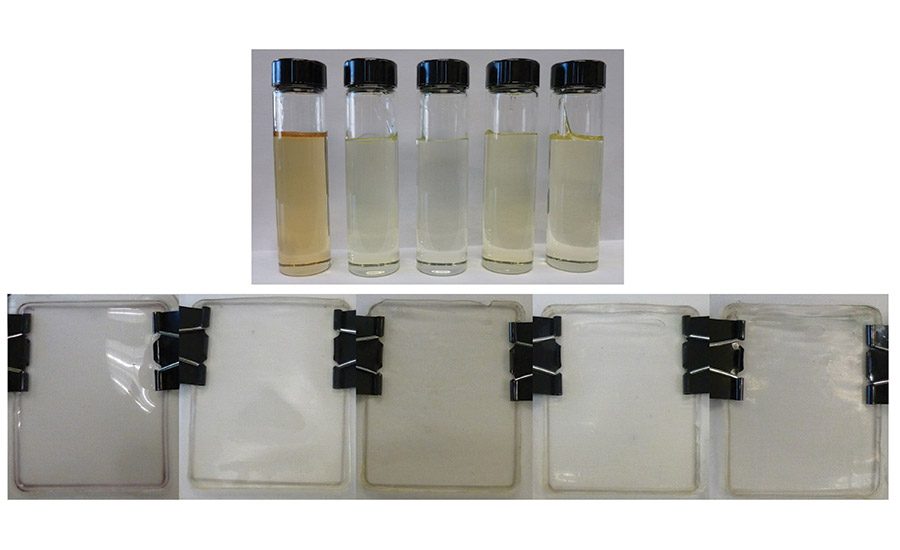

Figure 7. Thermal aging at 50°C for 77 days of the uncured (top) and cured (bottom) formulations, from left to right: no silane, Dynasylan® AMMO, Dynasylan® DAMO-T, SAS1, and Dynasylan® VPS 1142.

Figure 8. Accelerated weathering in the QUV for 24 hrs of the uncured (top) and cured (bottom) formulations, from left to right: no silane, Dynasylan® AMMO, Dynasylan® DAMO-T, SAS1, and Dynasylan® VPS 1142.

The hybrid adhesive and sealant market is projected to grow from $4.6 billion in 2016 to over $7.5 billion by 2022, at a CAGR of 8.6%.1 Silane-modified polymers (SMPs) are the resins of choice for this market, as they provide excellent adhesion and elasticity. SMP-based formulations find applications in construction, automotive, industrial assembly, DIY, and other market sectors.

In SMP-based formulations, amino-functional silanes are typically added as adhesion promoters that also promote crosslinking of the SMP as it cures upon exposure to moisture. In addition, fillers such as fumed silica are used for rheology and mechanical reinforcement, especially when optical clarity is desirable. Both the amino-functional silane and the fumed silica are necessary to achieve the desired appearance and performance of these formulations.

In recent years, there has been a focus on developing optically clear and colorless adhesive formulations. Maintaining a consistent appearance throughout aging, both in the cartridge and in the cured state, is crucial. This is being driven both by application performance and consumer demand for properties such as:

- Visibility—windows, windshields, electronic device screens

- Light transmittance—LEDs and other lighting fixtures, solar cells

- Design freedom—no need for color matching

- Aesthetics—“invisible” formula that does not leave a trace, reduced cleanup

In this work, we prepare an optically clear and colorless hybrid formulation using a silane-terminated polyurethane (STPU), which is a low-modulus moisture-reactive prepolymer resin. The general structure of the STPU is shown in Figure 1.

In addition, we use a hydrophobic surface-modified fumed silica, which provides rheology build, mechanical reinforcement, and anti-sagging properties while maintaining a high level of optical clarity. Finally, we incorporate a specialty amino-functional silane as a non-yellowing adhesion promoter that also helps further crosslink the STPU upon moisture curing. In this work, we demonstrate superior color stability performance of the specialty amino-functional silane Dynasylan® VPS 1142 compared to standard amino-functional silanes through various accelerated aging studies, both in the uncured (“in the cartridge”) and cured states.

Experimental

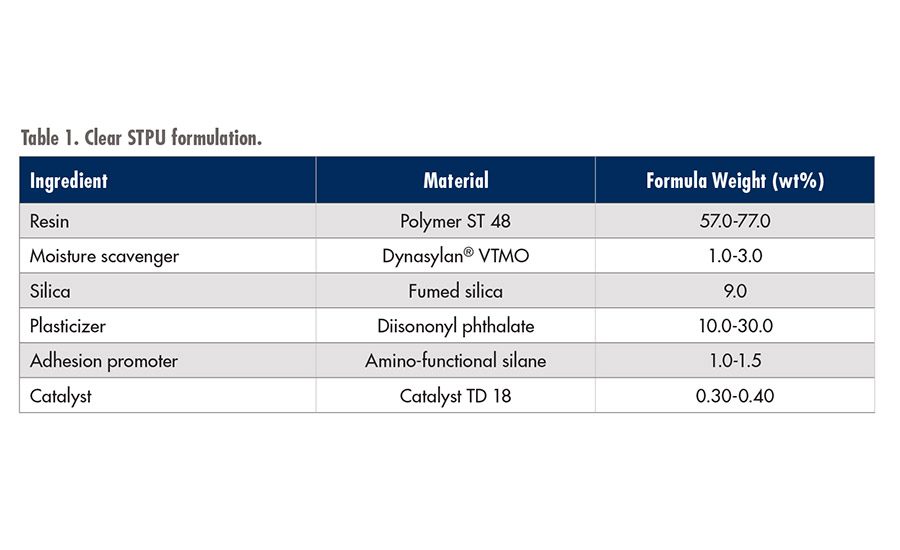

The optically clear formulations (see Table 1) were prepared using a Flack-Tek SpeedMixer®. Ceramic cylinders were used in order to properly disperse the fumed silica in the system and achieve optimal Hegman grind value. Initially, several surface-treated fumed silicas were screened for achieving optimum sag resistance and optical clarity. Once the optimal fumed silica was identified, several amino-functional silanes were screened in this formulation vs. a blank that did not contain any amino-silane inside. The silanes tested include standard amino-functional silanes Dynasylan® AMMO and Dynasylan® DAMO-T, a specialty amino-silane (SAS1), and Dynasylan® VPS 1142.

The formulations were tested as described in the Testing section, both in the uncured and cured state. The uncured specimens were kept in transparent vials and packed under dry nitrogen to mimic “in the cartridge” conditions. The cured specimens were allowed to cure for 21 days under ambient conditions (73°F, 50% relative humidity), as is typical for moisture-curable SMP-based formulations.

Testing

Boeing slump resistance testing (sag resistance) was performed according to ASTM D 2202: Standard Test Method for Slump of Sealants. The formulation is placed into the slump jig cavity and leveled out. The jig is then vertically placed in an oven set to 50 ± 2°C, and the plunger is pushed in to one-half of its maximum travel. The jig is removed from the oven after 30 min, and slump of the formulation is measured to the nearest 0.2 mm (0.01 in).

Thermal aging was performed at 50°C in the absence of light. Accelerated weathering was performed using an accelerated weathering tester (QUV from Q-Lab) and performed according to ASTM G 154. The discoloration of the specimens was monitored both qualitatively and quantitatively using a colorimeter (Datacolor Spectrum™ 400) over a period of 77 days. Color space measurements were performed every 7 days, and the b values (yellowness/blueness) are reported herein.

To measure skin formation time, a small mound of the formulation was allowed to cure under ambient conditions (25°C, 50% relative humidity). The mound was then touched by a wooden spatula every minute and checked for skin formation.

Cure-through time was measured using a Teflon mold filled with the formulation. The mold features a graduated slit of 1 cm wide and 25 cm long, as well as a graduated depth ranging from 0-10 mm from end to end. Cure through was monitored over time until a full 10-mm cure through was achieved.

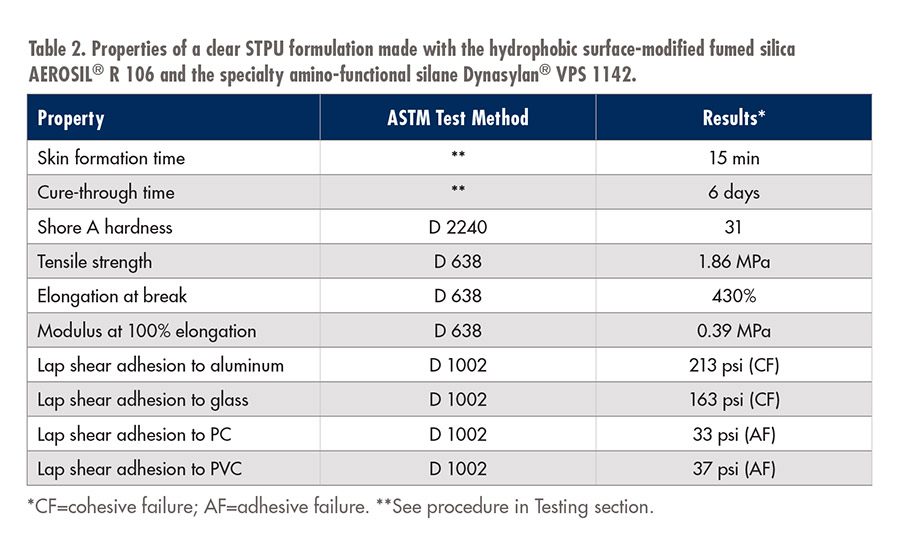

Lap shear adhesion, Shore A hardness, and mechanical testing (tensile strength, elongation at break, and modulus at 100% elongation) of the formulation containing the specialty amino-functional silane Dynasylan® VPS 1142 were performed according to the appropriate ASTM methods. See Table 2.

Results and Discussion

In this work, we utilized the previously mentioned STPU as the base resin for the formulation. STPUs undergo moisture-induced crosslinking. This crosslinking reaction is catalyzed typically by tin catalysts; amino-functional silanes can speed up this crosslinking reaction and also participate in it.

Since the objective of this work was to formulate an optically clear and colorless formulation, we utilized surface-treated fumed silica as a filler for rheology and mechanical reinforcement. We screened several fumed silicas in order to determine which would provide the best sag resistance while maintaining optical clarity. Figure 2 shows cured draw downs (2 mm dry thickness) of the formulation made with different fumed silicas, and Figure 3 shows the optical transmittance measured using a Turbiscan®. The selected fumed silica AEROSIL® R 106 showed good slump resistance and good optical clarity (> 97% light transmittance).

Amino-functional silanes are crucial components of SMP-based formulations. They accelerate and participate in the curing/crosslinking of the SMP, boost adhesion onto various substrates, and help develop the optimal mechanical properties of the cured formulation for best performance. Standard amino-functional silanes can be used in such formulations, but they tend to yellow significantly over time. In order to achieve an optically clear and colorless formulation, it is imperative to utilize an amino-functional silane that is color stable over time.

The specialty amino-functional silane Dynasylan® VPS 1142 in combination with the fumed silica AEROSIL® R 106 provides a highly optically clear and colorless formulation (see Figure 4). This formulation also exhibits superb slump resistance, as shown in Figure 5.

In order to assess the color stability of this formulation over time, thermal aging and accelerated weathering testing were performed, both on the uncured and cured formulation, and compared with the two standard amino-functional silanes, the specialty amino silane, and a formulation made without any amino-functional silane added. The results are summarized in Figures 6-8.

As the formulations were made without any UV stabilizer inside, the accelerated weathering in the QUV showed differentiation between the samples very rapidly (within 24 hrs), as compared to the thermal aging study done at 50°C. Surprisingly, the discoloration in the uncured state appears to be far worse in the formulation made without any amino-functional silane inside, indicating that the presence of an amino-silane helps protect the formulation in the cartridge from yellowing. On the other hand, in the cured state, the expected pattern is observed, where the standard amino-functional silanes lead to significant yellowing, and the specialty amino-functional silane Dynasylan® VPS 1142 shows the best color stability overall.

Further work is currently being done to elucidate the yellowing mechanism in such formulations. Our initial results indicate that the catalyst may play a crucial role in the color development as well.

Conclusions

Achieving a colorless, optically clear SMP-based adhesive formulation requires judicious choice of the SMP base resin, the fumed silica filler, and the amino-functional silane adhesion promoter. In this work, we have demonstrated that the color stability of the formulation over time upon aging is different “in the cartridge” vs. the cured state. Therefore, when optimizing a formulation for color stability, various accelerated aging tests (elevated temperature, UV light) should be utilized to get a holistic view of the performance.

In this work, we demonstrated that the combination of hydrophobic surface-modified fumed silica AEROSIL® R 106 and specialty amino-functional silane Dynasylan® VPS 1142 provides excellent optical clarity, good thickening and reinforcing properties, and superb slump resistance, while providing superior color stability in the cured state. Based on our results, we recommend the addition of UV stabilizers into the formulation to protect it from yellowing upon exposure to UV light.

For additional information, contact the lead author at sheba.bergman@evonik.com or visit www.evonik.com.

Authors’ note: Polymer ST 48, AEROSIL® R 106, Dynasylan® VTMO, Dynasylan® AMMO, Dynasylan® DAMO-T, SAS1, Dynasylan® VPS 1142, and Catalyst TD 18 are available from Evonik. Jayflex® diisononyl phthalate is available from Exxon Mobil.

Reference

- “Hybrid Adhesives & Hybrid Sealants Market by Resin Type (MS Polymer Hybrid, Epoxy-Polyurethane, Epoxy-Cyanoacrylate), Application (Building & Construction, Automotive & Transportation, Industrial Assembly), and Region-Global Forecast to 2022,” Markets and Markets, http://marketsandmarkets.com.

Editor’s note: This article is based on a presentation given at the Adhesive and Sealant Council’s 2019 Annual Spring Conference and Expo. For details regarding the council and its events, visit www.ascouncil.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!