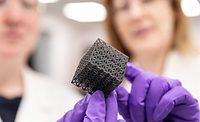

Henkel and Fortify Join Forces to Enable High-Performance Applications in 3D Printing

The combined solution reportedly leverages Fortify’s digital composite manufacturing (DCM) 3D printing technology, which mixes reinforcing fibers with Henkel’s resins, and then utilizes magnetics to align the fibers for optimum strength in printed parts.

Henkel and Fortify recently initiated a development agreement that allows both companies to mutually combine their areas of expertise and further drive the potential of additive manufacturing. Henkel reports that it has developed custom technology that enables durable, high-temperature and high-modulus resins. Through collaboration, Henkel has designed several formulations that allow Fortify to achieve new outcomes for industrial customers.

“This is a benchmark for the types of collaborations Henkel strives to cultivate,” said Ken Kisner, innovation lead for 3D printing at Henkel and founder of Molecule Corp., which was acquired by Henkel earlier this year. “Our strong, data-driven approach to material innovation continues to unlock the power of additive manufacturing. Fortify is focused on delivering value in industries where part performance is mission critical. Together we’re making it happen.”

The combined solution reportedly leverages Fortify’s digital composite manufacturing (DCM) 3D printing technology, which mixes reinforcing fibers with Henkel’s resins, and then utilizes magnetics to align the fibers for optimum strength in printed parts. “The Fortify platform enables our customers to leverage materials that weren’t conceivable, yet alone practical on other platforms,” said Joshua Martin, CEO and co-founder at Fortify. “With Henkel’s assistance, we are pushing this technology forward and solving the customer problems we expected as well as discovering exciting new opportunities.”

For more information, visit www.henkel.com and www.3dfortify.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!