Improving Efficiency and Sustainability in Composites Bonding

A new system comprising a curing oven, regenerative thermal oxidizer (RTO), and secondary and tertiary heat exchangers can help reduce operating costs while ensuring the safe removal of volatile organic compounds during composite bonding processes.

Figure 1. As the exhaust stream passes through the energy recovery chamber, the “cold” ceramic media mass absorbs the exhaust stream’s thermal energy and stores the thermal energy for the system’s reverse flow sequence.

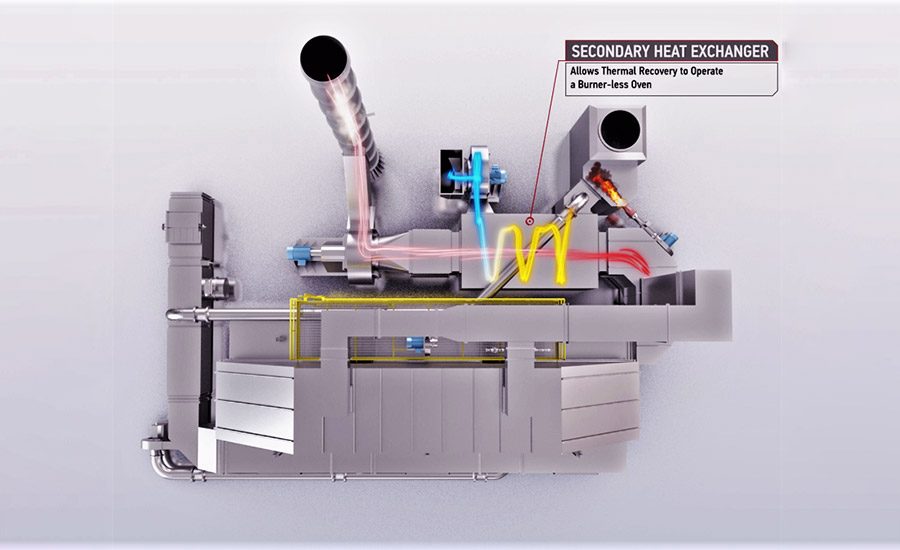

Figure 2. The secondary heat exchanger then transfers heat indirectly from the “clean” RTO outlet exhaust to a secondary process stream that supplies hot air to the curing oven.

Among all chemical curing techniques, convection and radiant thermal curing represent the most widely used applications for adhesives and sealants. During the curing process, adhesives and sealants usually pass through two physical transformations—evaporation and condensation—while being applied to other materials.

In addition to physical changes, the specific temperatures cause chemical changes in adhesives and sealants at a molecular level, where polymer chains’ crosslinking occurs. Crosslinking represents the final step of polymerization, which optimizes the tensile strength of the material and solidifies the adhesive bonds in the curing process. Achieving this critical threshold requires not only predetermined temperature ranges but also humidity levels, pressure, and retention times.

Curing in Composite Applications

Thermal curing of adhesives and sealants is used in unlimited industrial and product manufacturing processes. The composites materials industry has been gaining significant attention in recent years. The use of composites, especially in the automotive and aerospace industries, is rising due to a tendency to decrease the weight of cars and airplanes and reduce greenhouse gas emissions. The composite materials in these industries must meet specific tensile strengths and load-bearing properties, making the material durable under extremely high temperatures and pressures.

Three composite bonding methods that include adhesive application (e.g., secondary bonding, co-bonding, and co-curing with the adhesive) mostly differ in curing schedule, but they all present heat-cure methods. In all cases, the adhesive composition must be precisely designed to meet requirements under a broad range of conditions, which is why high-performance nanomaterial reinforcements are common in adhesives for composite materials.

In the curing process, during the phase transformation of epoxy resins, polyurethane, phenol-formaldehyde resins, and other organic compounds, significant toxic volatile organic compound (VOC) emissions are produced. Due to strict governmental regulations, air pollution control equipment must be in place to keep these VOCs from evaporating into the atmosphere and causing negative impacts on the environment and harm to human health. However, treating this VOC-rich flue gas is complex, as it is contaminated with a wide range of compounds with different properties. Consequently, the VOCs’ complete absorption from the flue gas is hardly feasible and extremely expensive since multiple liquid absorbents would be needed. In addition, those gases would then need to be desorbed from the liquid in the second treatment stage and then disposed of as toxic waste.

Therefore, the most efficient method of VOC treatment is oxidation under high temperatures, converting VOCs entirely into water and carbon dioxide. The oxidation occurs in combustion chambers at temperatures determined in correspondence with present volatile compounds, their concentration in the flue gas stream, and, consequently, the lower explosion level (LEL) of the flue gas. However, the thermal treatment of VOCs requires high operating temperatures of up to 1,500-1,600°F for 99%+ VOC removal, causing a significant increase in the plant’s variable costs and significantly increasing energy demands.

A New Solution

After adhesives and sealants are applied, the bonding process occurs in curing ovens where temperatures are often greater than 200°F and with retention times in the range of 15 min to 24 hrs or longer, which is the case with some epoxy adhesives. For optimal and uniform bonds, it is essential to control the following process parameters accurately: temperature, atmospheric pressure, and retention time of each process stage. This requires real-time control with custom-made software due to multiple transitions of process temperatures that should be executed in the shortest periods.

A patented solution has been developed for the composites industry to address these key operating challenges. The system, which comprises a composite curing oven, regenerative thermal oxidizer (RTO), and secondary and tertiary heat exchangers, ensures 95%+ heat recovery efficiency and 99%+ VOC destruction rate efficiency (DRE).

The RTO comprises three combustion chambers where flue gas enters alternately, designed for 1.0-sec or more residence time. After the flue gas temperature has been elevated in the RTO combustion chamber, the oxidized process exhaust stream then passes through a second energy recovery chamber. During this time, a third energy recovery chamber is being purged. As the exhaust stream passes through the energy recovery chamber, the “cold” ceramic media mass absorbs the exhaust stream’s thermal energy and stores the thermal energy for the system’s reverse flow sequence (see Figure 1).

Once the first chamber’s thermal energy has been depleted through the incoming primary process exhaust stream’s absorption, the flow through the system is switched. This results in the incoming VOC-laden process exhaust being directed through the previous absorption chamber saturated with thermal energy. The oxidized exhaust stream goes through the previously purged chamber. By using this airflow reversal method through the ceramic media beds, a minimal supply of heat from the burners is needed to ensure the incoming exhaust stream meets the system’s minimum operating temperature. The ceramic media beds’ shape and sizing ensure a 95%+ heat recovery efficiency.

Based process parameters such as volume flow, flue gas VOC concentration, and lower explosive limit, the regenerative thermal oxidizer can be sized and designed specifically to meet all requirements. The system is supplied with burners with more than a 20:1 turndown ratio and combustion air fans controlled via variable-frequency drive (VFD). These features are essential for manufacturers with multiple production lines that have different working parameters or, alternatively, one production line whose operational functions may vary significantly, which is often the case with curing processes.

Regardless of the flue gas stream temperature and volume flow changes, the combustion chamber’s set temperature will be achieved by automated combustion air and natural gas flow adjustment, meeting the desired excess air ratio and combustion efficiency at all times. The combustion chambers’ temperatures depend on the nature of the adhesive and sealants involved. They often may be up to 1,500-1,600°F to enable the complete oxidation of the VOCs, leaving a tremendous latitude to use the exhaust stream as the heat source for plant processes.

The oxidized process exhaust air stream then exits the ceramic bed and enters an outlet manifold that supplies the treated air stream to the secondary heat exchanger. This secondary heat exchanger then transfers heat indirectly from the “clean” RTO outlet exhaust to a secondary process stream that supplies hot air to the curing oven (see Figure 2). This significantly reduces the required heat to be supplied by the oven burners, reducing gas usage and oven burner-generated NOx emissions. In many installations, this allows the burners on the ovens to be turned off or removed from service.

Since there are two requirements for air entering the curing oven (pressure and temperature), it is important to control the process air flow with a variable-frequency drive in real time. Suppose the oxidized exhaust stream’s temperature is too elevated. In that case, its flow is reduced by stream separation into one stream that passes through the second heat exchanger, and another bypass stream is sent back to the RTO inlet.

On one side, this regulation of the exhaust stream volume flow allows the maintenance of the desired secondary process stream temperature. On the other side, the mixing of a hot bypass stream with the RTO inlet stream significantly reduces fuel and combustion air requirements to maintain combustion chamber operating temperature. Another case is where the fresh air temperature requirements are higher than feasible at the heat exchanger outlet. In this event, the booster burner at the exchanger outlet provides additional heat by controlled gas combustion according to the specified temperature.

The last step of the oxidized air treatment is entering the tertiary heat exchanger fluidly connected to a water source conduit, a coil, and a heated water outlet conduit. The air-to-water heat exchanger recovers a significant portion of the remaining waste heat in the exhaust air stream by preheating the circulating water in the economizer coil. The heat absorbed by water may be sufficient in phenol-formaldehyde adhesive production, where phenol, formaldehyde, water, and catalyst should be heated to around 160°F. The heated water is often used to heat the adhesives or sealants batches indirectly.

This system provides an optimal solution for the 99%+ removal of VOCs from the flue gas while simultaneously generating thermal energy for the curing ovens and raising the water temperature necessary for heating adhesives or sealants in chemical solutions. In this way, process heating and gas treatment units are integrated into one process unit and controlled remotely.

Custom Controls

Accurate control of the curing process is highly demanding due to the need for multiple sessions with different retention times, operating pressures, and temperatures. A custom control system enables users to achieve a wide range of controlled variables’ set values while always maintaining maximum heat efficiency. The human interface allows a user to define target values of:

- Combustion temperature in chambers, securing complete and continuous VOC removal

- Air process stream temperature and volume flow, subsequently suppling the specified heat and pressure to the curing ovens for various steps of the curing process

- Water temperature for a chemical solution or indirect heating purposes

The user may define the production process’ algorithm with the set values of controlled variables in up to 11 different steps. The system’s dynamic state between steps is minimal due to specially tuned programmable logic controllers (PLCs) that enable short settling time and fast achievement of a set point in a particular range that the customer specifies. The connected software enables users to define the set values in every process step a priori instead of manually entering the values during the process.

Optimal Operations

Using this system significantly reduces a plant’s operating costs in terms of natural gas and electricity demands due to its highly efficient process integration and the optimal control system. Most importantly, this integrated system is designed to ensure that the gases discharged into the atmosphere meet stringent air quality standards at all times.

For more information, visit https://epconlp.com.

Note: Images courtesy of Epcon Industrial Systems.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!