Home » tapes

Articles Tagged with ''tapes''

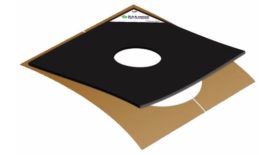

Curbside-Recyclable Tape Offers Sustainable Carton Sealing

The sustainable solution offers a secure seal, versatile sealing applications, and can be recycled right on the box.

May 21, 2024

Orlando Welcomes Tape Professionals for Tape Week 2024

The premier event for professionals in the PSA tape industry, Tape Week 2024 is taking place April 29 to May 2, 2024, at the Hilton Orlando.

April 23, 2024

Reversible Glue and Customizable Bio-Adhesive Patches: The Latest Adhesion Science

New research in adhesion science includes a reversible glue developed by a team at Newcastle University and customizable bioadhesive patches created by scientists at Pohang University of Science and Technology in Korea.

April 17, 2024

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing