Home » ultraviolet (UV) curing

Articles Tagged with ''ultraviolet (UV) curing''

UV Curing Technology Helps Transform the Manufacturing of EV Batteries

Offering reduced process times, higher throughput, lower rejection rates, and environment-friendly benefits, UV curing systems are helping to revolutionize lithium-ion battery manufacturing.

September 15, 2022

Previewing RadTech UV+EB 2022

Attendees of RadTech UV+EB 2022 can expect over 100 informative presentations, multiple educational opportunities, and a comprehensive exhibition showcasing the latest in ultraviolet- and electron beam-related technologies.

May 3, 2022

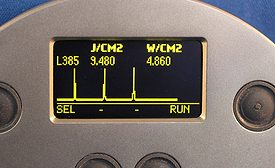

EXCELITAS TECHNOLOGIES CORP.: Next-Generation Spot UV Curing System

The system features proprietary OmniCure closed-loop feedback control technology, which automatically monitors and maintains the optical output for a repeatable curing process.

November 30, 2021

Excelitas to Highlight Curing Systems for Medical Device Manufacturers at MD&M Minneapolis

MD&M Minneapolis will take place November 3-4 at the Minneapolis Convention Center.

November 3, 2021

Understanding and Measuring UV LEDs

It is important to consider the variables associated with the LED source and proper measurement tools in order to understand, maintain, and control the adhesive curing process.

October 6, 2021

The Importance of Uniform Light Delivery from UV Curing Systems

Beyond peak intensity and curing area, differences in uniformity can impact the delivered UV light dose and change the optimal setup for flood-curing systems.

September 13, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing