Home » films

Articles Tagged with ''films''

Top 5 News that Sticks

Last week, news about 3M’s films business received the most reader interest.

Read More

Ashland, Mark Andy Launch Labeling Technology

Ashland Inc. and Mark Andy Inc. recently announced they have launched a film lamination technology.

September 19, 2016

3M to Sell Temporary Protective Films Business

3M recently has entered into an agreement to sell the assets of its temporary protective films business to Pregis LLC.

September 16, 2016

Window Film and Affordable Sustainability

Window film provides nearly all of the benefits of other green upgrades at a fraction of the cost.

May 2, 2016

Advancing Adhesives

Material Solutions for Medical Wearables

Films allow sensitive electronics to be directly embedded more efficiently.

May 2, 2016

Advancing Adhesives

Breakthrough Improvements in Touchscreen Production

A new manufacturing process allows touchscreens to be flexible, curved, 3-D or wearable.

February 1, 2016

Increasing Production Marketing, Uptime and Throughput in Packaging Applications

Automatic splicing machines can ultimately provide greater line profitability.

February 1, 2016

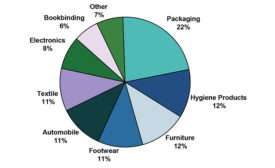

Top 10 ASI Market Trends Stories of 2015

Reports focused on adhesives and sealants in several end-use sectors drew a lot of interest.

December 1, 2015

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing