Home » sealants in packaging

Articles Tagged with ''sealants in packaging''

Ebeam technology continues to become more recognized as a safe and effective crosslinking and curing option.

Read More

Bostik Receives Supplier Innovation Award

Bostik recently announced it has received American Packaging Corp.’s (APC) first Supplier Innovation Award.

May 2, 2016

Top 5 News that Sticks

News About RPM’s Acquisition Again Receives Most Interest

Readers were most interested in news about RPM’s acquisition for the second consecutive week.

March 21, 2016

Market Reports

European Waterborne Adhesives, Active and Intelligent Packaging, Construction Chemicals

The waterborne adhesives market in Europe was estimated at $3.26 billion in 2014 and is projected to grow at a compound annual growth rate (CAGR) of 5.8%.

March 1, 2016

Market Trends

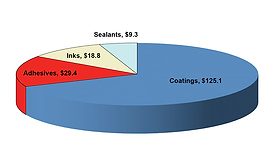

Coatings, Adhesives, Sealants and Inks Continue to Grow

The global consumption of coatings, adhesives, sealants and inks (CASI) is being driven primarily by construction applications.

March 1, 2016

Market Trends

UV-Curable Ink Applications Increase

Growth in the UV-curable ink market is being spurred by increased use in food and beverage packaging.

February 1, 2016

Market Trends

Convertible Flexible Packaging Demand Increases

Growth areas for flexible packaging include both food and nonfood applications.

February 1, 2016

Increasing Production Marketing, Uptime and Throughput in Packaging Applications

Automatic splicing machines can ultimately provide greater line profitability.

February 1, 2016

Case Study

Failure-Free Gluing for Custom Boxes

A corrugated converter cuts defects to near zero and increases output and customer satisfaction with new gluer, detection, and trim systems.

February 1, 2016

Hot-Melt Adhesive System Solution

New melting technology provides savings by eliminating traditional hot-melt challenges.

January 4, 2016

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing