Home » threadlockers

Articles Tagged with ''threadlockers''

Maintenance, repair, and operations engineers can benefit from the sustainability and operational benefits of engineering adhesives.

Read More

Ask Dr. Dave

Ask Dr. Dave’s Greatest Hits

Dave Dunn has retired as a columnist following 20 years of monthly contributions.

February 21, 2022

Ask Dr. Dave

Vibration- and Shock-Resistant Adhesives

Which adhesives can resist serious vibration and shocks?

October 20, 2021

BOSTIK: Anaerobic Engineering Adhesives

These adhesives offer a number of advantages over mechanical solutions, such as long-term reliability, increased versatility of application, and protection against corrosion.

October 7, 2021

How Can Adhesives and Sealants Improve Equipment Reliability?

When implemented correctly, adhesives and sealants can play a critical role in improving equipment reliability and lowering maintenance and operational costs.

June 10, 2021

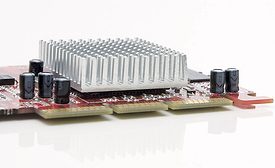

Adhesives for Electronics Assembly

Adhesives provide a strong bond during electronics assembly while protecting components against potential damage.

March 29, 2021

Marine Applications for Adhesives and Sealants

Today’s marine adhesives and sealants provide strong lightweight bonds to structural components and watertight sealing between substrates.

September 8, 2020

DAP: Repair Adhesives

The Tank Bond family of products includes Tank Bond Thread Stopper, Tank Bond Liquid Grip, Tank Bond Heavy Duty Advanced Epoxy, Tank Bond Clear Epoxy, and Tank Bond Thread Locker.

August 20, 2020

Ask Dr. Dave

Solvent-Based Adhesives

I was brought up using solvent-based adhesives, but they don’t seem to be as common these days. Is it just a safety issue? Are any of these adhesives still available?

August 4, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing