Home » LED curing

Articles Tagged with ''LED curing''

Adhesive bonding, sealing, and coating processes in factory assembly lines are rapidly upgrading to UV LED curing technology.

Read More

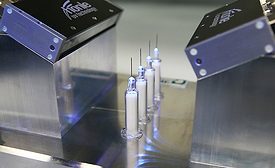

PANACOL, HӦNLE, AND BDTRONIC: Smart System Solution for Medical Assembly

As needles are produced in large quantities, rapid and reliable bonding is essential.

April 1, 2021

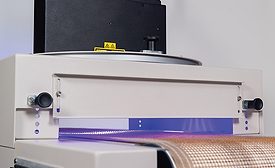

DIGITAL LIGHT LAB: LED Curing Panel

The AccuCure panel is available in several different wavelengths, including 285, 365, 400, 420, 435, and 445 nm, among others.

March 9, 2021

PHOSEON TECHNOLOGY: UV LED Curing Lamps

These UV LED curing lamps are reportedly designed primarily for markets where high power in a compact form factor is a key requirement.

February 16, 2021

Product Profile

Light It Up: Curing Solution for High-Speed Electronics and Automotive Environments

A new LED lamp was developed for high-speed production in the electronics and automotive industries in environments that require small areas to be irradiated and equipment to be easily integrated into existing systems.

February 15, 2021

RadTech North America Joins U.S. Plastics Pact

The U.S. Plastics Pact looks to define problematic or unnecessary packaging, working toward the increased use of reusable, recyclable, or compostable materials.

December 28, 2020

UV Curing of Adhesives and Sealants in Green Manufacturing

UV LED curing offers multiple environmental and productivity benefits compared to traditional mercury bulbs.

May 6, 2020

Excelitas Technologies to Showcase LED UV Curing Systems at RadTech UV+EB 2020

In addition to Excelitas’ booth at RadTech, Marvin Ruffin, business development manager, will present a session entitled “Preventing Hospital-Acquired Infections with UVC LEDs” during the co-located 2020 IUVA Americas Conference UV for Healthcare Applications Track.

March 3, 2020

PHOSEON: Area Curing Solution

Phoseon reports that the new FJ801 light source is designed primarily for production environments that require area curing, such as manufacturing lines for micro-speakers and camera modules.

February 20, 2020

Manufacturing Conversion: Transitioning from Conventional UV to LED Curing

While the process steps in a UV LED manufacturing conversion are slightly more involved than a direct-swap mercury replacement, the benefits are often significant and well worth the time and effort.

February 10, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing