Home » rigid packaging

Articles Tagged with ''rigid packaging''

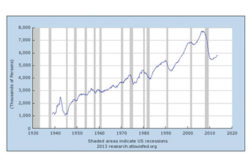

Recovery in the U.S. continues on solid footing, with the construction sector finally showing solid signs of growth.

Read More

Top 5 News that Sticks

Celanese Brand Reorganization Tops the List

This weekly roundup highlights the news stories that garnered the most attention during the previous week.

October 28, 2013

Improving Performance of Hot-Melt Packaging Adhesives

Pure monomer resins can help improve the performance of EVA-based carton closure hot-melt packaging adhesives.

October 1, 2013

Product Profile: Simplifying Case and Carton Sealing

A new hot-melt delivery system is designed to improve uptime and deliver cost savings.

May 1, 2013

Is it Time to Decouple from Petroleum?

Bio-polymers have entered the market, and demand is expected to grow rapidly over the next decade.

August 1, 2010

Packaging EndUser: Starch- and Dextrin-Based Adhesives

Starch- and dextrin-based adhesives play a large part in industrial production, especially the packaging industry.

August 1, 2005

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing