Home » light-cure adhesives

Articles Tagged with ''light-cure adhesives''

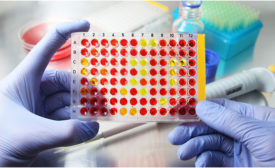

Adhesives and tapes used for diagnostics are faced with different challenges than those for skin contact and other medical applications.

Read More

SHURTAPE TECHNOLOGIES LLC: UV-Cured Acrylic Adhesive for Building Envelope Applications

Shurtape reports that ShurGRIP maintains high shear strength at temperatures up to 248˚F (120˚C), creating permanent, durable seals in all climates.

November 18, 2021

UV-Cured Acrylic Adhesives for Building Envelope Applications

The characteristics of ultraviolet (UV)-cured acrylic adhesives outweigh alternatives when health, the environment, longevity, and durability are priorities.

November 12, 2021

MASTER BOND: LED-Curable Adhesive

LED405FL3 is a low-viscosity system that can be used for small potting and encapsulation applications, assuming that there are no shadows or concealed areas.

November 9, 2021

LOHMANN CORP.: Color-Changing, UV-Cure Epoxy Adhesive

A fast acting epoxy resin, it is reported to be stronger and more resilient than pressure-sensitive adhesive tapes and liquid adhesives.

November 2, 2021

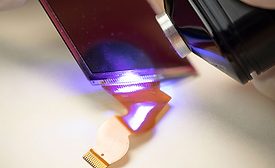

PANACOL: Biocompatible UV Adhesive for Soft Plastics

Vitralit UV 7030 is a one-component, solvent-free, UV-curable acrylic adhesive.

October 19, 2021

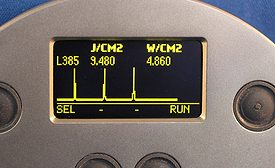

Understanding and Measuring UV LEDs

It is important to consider the variables associated with the LED source and proper measurement tools in order to understand, maintain, and control the adhesive curing process.

October 6, 2021

The Importance of Uniform Light Delivery from UV Curing Systems

Beyond peak intensity and curing area, differences in uniformity can impact the delivered UV light dose and change the optimal setup for flood-curing systems.

September 13, 2021

Phoseon Exhibits LED Curing Solutions at Adhesives & Bonding Expo

Company representatives shared details regarding LED technology.

July 20, 2021

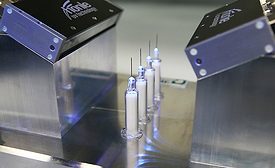

PANACOL, HӦNLE, AND BDTRONIC: Smart System Solution for Medical Assembly

As needles are produced in large quantities, rapid and reliable bonding is essential.

April 1, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing