Adhesives and Sealants Topics

Advancing Adhesives

A new manufacturing process allows touchscreens to be flexible, curved, 3-D or wearable.

Read More

Ask Dr. Dave

How do I disassemble nuts and bolts that were assembled using anaerobic threadlockers, then re-use the fasteners?

Threadlockers are generally comprised of three common types.

February 1, 2016

Four Ways to Improve Communication at Work

It is possible to build better workplace relationships by communicating clearly and confidently.

February 1, 2016

Market Trends

UV-Curable Ink Applications Increase

Growth in the UV-curable ink market is being spurred by increased use in food and beverage packaging.

February 1, 2016

Market Trends

Convertible Flexible Packaging Demand Increases

Growth areas for flexible packaging include both food and nonfood applications.

February 1, 2016

Increasing Production Marketing, Uptime and Throughput in Packaging Applications

Automatic splicing machines can ultimately provide greater line profitability.

February 1, 2016

Transforming the World through Technology

Experts believe these three technologies will have great potential in the next five years.

February 1, 2016

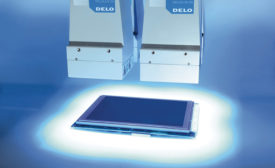

Curing Adhesives: When Less Intensity Is More

More intensive curing lamps can accelerate the production process of light-curing adhesives, but only up to certain limits.

February 1, 2016

Regulatory Review

The TSCA Miracle of 2015

Passage of the Toxic Substances Control Act (TSCA) is almost a reality.

February 1, 2016

Focus On

Sticking with Science

A new company spun off from the research labs of Carnegie Mellon University is commercializing gecko-inspired dry adhesives.

February 1, 2016

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing