Adhesives and Sealants Topics

Hot-Melt Adhesive System Solution

New melting technology provides savings by eliminating traditional hot-melt challenges.

January 4, 2016

Ask Dr. Dave: How can I tell if my adhesive has fully cured?

Maximum properties for epoxies are only achieved by curing at high temperatures for long periods of time to complete the reactions.

January 4, 2016

Focus On: Henkel is Connecting to Success

Effectively capturing regional opportunities is crucial to success for adhesives and sealants manufacturers in today’s manufacturing environment.

January 4, 2016

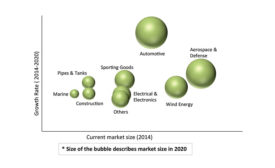

Market Trends: Lightening Up with Carbon Fiber-Reinforced Plastics

The market for carbon fiber-reinforced plastics composites is projected to grow 9.9% between 2015 and 2020, mainly due to demand in the aerospace and defense and automotive sectors.

January 4, 2016

Focus On: H.B. Fuller Grows through Acquisitions

Acquisitions in adhesives and sealants can help fast-track engineering adhesives innovation.

January 4, 2016

Case Study: Enhancing Efficiency in Adhesives and Coatings Manufacturing

Bulk bag weigh batching helps an adhesives and coatings manufacturer increase productivity.

January 4, 2016

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing