Converting/Packaging

Is it Time to Decouple from Petroleum?

Bio-polymers have entered the market, and demand is expected to grow rapidly over the next decade.

August 1, 2010

Peel Adhesion Testing of Small or Problem Labels

Small labels can be tested using modified standard methods.

October 1, 2009

Packaging EndUser: Starch- and Dextrin-Based Adhesives

Starch- and dextrin-based adhesives play a large part in industrial production, especially the packaging industry.

August 1, 2005

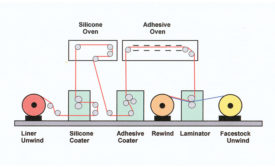

Manufacturing Pressure-Sensitive Adhesive Products: A Coating and Laminating Process

How are pressure-sensitive adhesives made?

April 1, 2005

An Overview of Emulsion Polymers Used in the Adhesives Industry

Demand for adhesive emulsions is forecast to expand 4.4 percent per year to 2.3 million metric tons in 2005.

June 30, 2002

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing