Pressure-Sensitive Adhesives (PSAs)

Pressure-Sensitive Adhesives 101

This article explains what a pressure-sensitive adhesive is, how it is constructed and what adhesive options are available.

October 1, 2009

Peel Adhesion Testing of Small or Problem Labels

Small labels can be tested using modified standard methods.

October 1, 2009

Adhesive Tapes as Trace Evidence

When adhesive tape is found as evidence at a crime scene, it is the forensic scientist’s job to match it to its source with little or no knowledge of tape construction.

January 1, 2008

Biodegradable Polymers in Adhesive Systems

Many biodegradable polymers are suited for adhesive applications, such as environmentally friendly packaging, recyclable envelope adhesives and biomedical devices.

June 1, 2007

Safety First: Safe Handling of Adhesives and Sealants

While cured adhesives and sealants are generally considered safe, care must be taken with airborne particles, decomposition products, and uncured components.

March 1, 2007

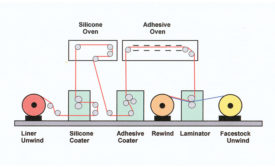

Manufacturing Pressure-Sensitive Adhesive Products: A Coating and Laminating Process

How are pressure-sensitive adhesives made?

April 1, 2005

An Overview of Emulsion Polymers Used in the Adhesives Industry

Demand for adhesive emulsions is forecast to expand 4.4 percent per year to 2.3 million metric tons in 2005.

June 30, 2002

Hot-Melt Polyurethane Reactive Adhesives Targeted for Specific Applications

What are hot-melt polyurethane reactive adhesives used for?

January 26, 2001

Pressure-Sensitive Adhesive Testing

Testing pressure-sensitive adhesives under standard conditions of temperature and relative humidity is always a preferred means to compare data from lab to lab and from lot to lot, but it is sometimes necessary to evaluate the performance of an adhesive under conditions that it would encounter in the field.

September 11, 2000

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing