Testing/Quality Control

Many factors need to be considered when devising meaningful viscosity tests for adhesives and sealants.

Read More

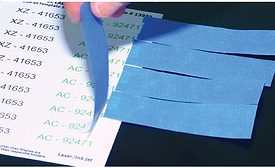

Peel Adhesion Testing of Small or Problem Labels

Small labels can be tested using modified standard methods.

October 1, 2009

Adhesive Tapes as Trace Evidence

When adhesive tape is found as evidence at a crime scene, it is the forensic scientist’s job to match it to its source with little or no knowledge of tape construction.

January 1, 2008

Adhering to Difficult Substrates with Silicone Adhesives

Substrates with reactive groups available for bonding make chemical bonding easier to achieve, while substrates with nothing to react to make adhesion difficult.

October 1, 2005

Understanding Viscoelastic Damping and Treatments Using Typical Adhesive Materials

Analytical tools are now available to engineers and product designers challenged with the task of reducing the radiated noise and vibration levels of structures.

May 29, 2002

U.S. Sealant Standards in Building Construction

Sealants must be applied according to the manufacturer’s instructions, which generally correspond with industry guides and practices.

April 20, 2001

Pressure-Sensitive Adhesive Testing

Testing pressure-sensitive adhesives under standard conditions of temperature and relative humidity is always a preferred means to compare data from lab to lab and from lot to lot, but it is sometimes necessary to evaluate the performance of an adhesive under conditions that it would encounter in the field.

September 11, 2000

ISO 9000:2000 - The New Quality Standard

ISO 9000 has been revised—but the new standard, called ISO 9000:2000, is a radical revision and the industry has questions.

April 17, 2000

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing