Manufacturers

RTM certification acknowledges and raises the visibility of PSTC member companies that invest in being responsible tape manufacturers.

Read More

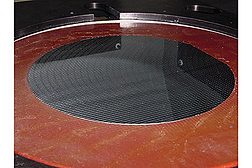

Recent Advances in Die-Attach Film Adhesives

Die-attach film adhesives can enable more advanced technology for packaging semiconductor devices.

November 1, 2014

FAQs about Pressure-Sensitive Adhesives (PSAs)

Brands and label converters must consider several factors when choosing a pressure-sensitive adhesive for their application.

November 1, 2014

A Sealant Solution

Vinyl acetate ethylene binders provide a cost-effective option for sealant applications without compromising formulation quality.

November 1, 2014

Focus On: New Technology Enables Self-Adhesive Media to be Removed Without a Trace

A new rubber formulation allows for easily removable self-adhesive print media.

November 1, 2014

UV/Vis Energy-Cure Adhesives and Sealants: Industry Trends, Chemistry, and Packaging

Applications for energy-cured coatings, adhesives and sealants have grown rapidly.

November 1, 2014

Handicapping the Field: How Next-Generation Solar PV Materials Will Emerge into the Market

The search is on for materials platforms that improve the conversion efficiency of solar panels.

November 1, 2014

CE Marking Compliance: Risks and Rewards for Sealant Manufacturers

Sealant manufacturers should be aware of the new harmonized European Standard for the construction industry.

November 1, 2014

Focus On: Adhesives and Coatings Manufacturer Undergoes an Environmental Upgrade

Innovative energy-efficient equipment will help LORD reduce its environmental impact.

November 1, 2014

Carbon Dioxide-Based Polycarbonate Polyols for Polyurethane Systems

PPC polyols are a sustainable, low-cost option with performance properties exceeding those of conventional polyols in polyurethane RHM adhesives.

November 1, 2014

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing