Manufacturers

The relationship between distributors and manufacturers in the adhesives and sealants industry has evolved far beyond simple product delivery.

Read More

Ask Dr. Dave: How can we get our adhesives approved for food/beverage or medical applications?

Dave Dunn's July 2014 column.

July 1, 2014

Automation in the Metering, Mixing and Dispensing of Adhesives and Sealants

Diverse automation and manual metering, mixing,and dispensing options are necessary to suit a variety of industrial applications.

June 2, 2014

Case Study: Air-Operated Double-Diaphragm Pumps Provide the Glue of the Operation for an Adhesives Manufacturer

Air-operated double-diaphragm pumps offer multiple benefits for adhesive and sealant manufacturing operations.

June 2, 2014

Rapid Adhesive Bonding by Induction and Microwave Curing

Induction and microwave curing procedures must be evaluated and customized according to the specific application.

June 2, 2014

Advancements in UV LED Curing Technology for Adhesives

The gaps that previously existed between traditional lamp solutions and UV LED-based curing systems have been narrowed.

June 2, 2014

Focus On: Adhesive Mixing Technology Can Help Facilitate Sustainability in Dental Practices

A new adhesive mixing technology can save money by reducing materials consumption.

June 2, 2014

Carbon Fiber: Strong Bonds, Strong Growth

Adhesives provide multiple advantages when bonding carbon fiber composite materials.

June 2, 2014

Innovation and the Future of Liquid Filling Machines for Adhesives and Sealants

Nozzles and gravity-fed direct-fill systems can improve filling accuracy and throughput.

June 2, 2014

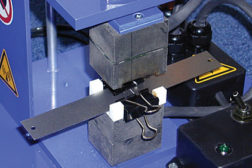

Case Study: Ammunition Sealant Dispensing System

A custom ammunition sealant dispensing system reduces production costs and saves time while increasing accuracy and quality.

June 2, 2014

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing