Columns

Which articles have been most useful to you, and which ones did you skip over?

Read More

Ask Dr. Dave: April 2013

Dave Dunn shares details regarding UV adhesives/coatings for a medical device assembly.

April 1, 2013

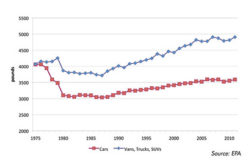

Strategic Solutions: Fuel Economy Standards and the Adhesives Market

Robust demand is expected to offer opportunities for adhesives.

March 1, 2013

Editor’s Memo: Materials Handbook

Welcome to our annual Raw Materials, Chemicals, Polymers and Additives Handbook.

March 1, 2013

Ask Dr. Dave: February 2013

Dr. Dave answers a question about the recycling of adhesives and sustainability in the adhesives industry.

February 1, 2013

Regulatory Review: Categorical Considerations for VOC Regulation

Some products that are considered to be coatings may not lie within the architectural coatings rule, but may instead cross over to adhesives and sealants rules—or even others.

February 1, 2013

Editor’s Memo: Electronics Applications

CEA's 2013 International CES event was held last month; Electronics West will be held this month.

February 1, 2013

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing