End User Features

Flexible Formulation of Waterborne Caulks and Sealants

Eliminating external plasticizers can improve performance in waterborne caulks and sealants.

July 3, 2017

PSTC Tape Summit Honors Past, Looks to Future

The tapes-focused event celebrated the 40th anniversary Tech Seminar.

July 3, 2017

Case Study

Carbon Dioxide Collaboration

A pressure-sensitive adhesive applied on optical sensors is contributing to life-support systems such as mixed gas rebreathers.

July 3, 2017

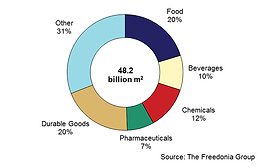

Flexible Plastic Packaging Market to Grow 5%

Market growth in flexible plastic packaging is due to an increase in manufacturing activities and rising demand for conveniently packaged products.

July 3, 2017

Market Trends

Label Demand Rolls Ahead

Pharmaceutical label demand is expected to grow more than 7% annually through 2020.

July 3, 2017

Ask Dr. Dave

We want to bond steel to foamed polystyrene. What do you recommend?

Dave Dunn's July 2017 column.

July 3, 2017

Nondestructive Inspection for Heat Sink Efficiency

Acoustic micro-imaging tools produce acoustic images of internal features, including gaps, in electronic components.

June 1, 2017

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing