Featured on Home Page

Alternative mixing strategies can offer a smarter way of producing adhesives and sealants.

Read More

A Safer Alternative Takes the Pressure out of Formulating Pressure-Sensitive Adhesives

A new, tetrafunctional epoxy reactive modifier is increasingly being used as non-mutagenic, drop-in formulation replacement for polyfunctional aziridine.

March 1, 2016

Focus On

Wilden Celebrates 60 Years

A flood at a steel factory led to the invention of the air-operated double-diaphragm (AODD) pump.

March 1, 2016

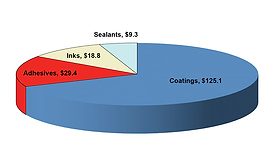

Market Trends

Coatings, Adhesives, Sealants and Inks Continue to Grow

The global consumption of coatings, adhesives, sealants and inks (CASI) is being driven primarily by construction applications.

March 1, 2016

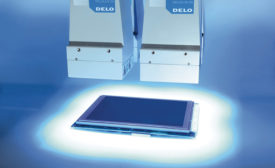

Advancing Adhesives

Breakthrough Improvements in Touchscreen Production

A new manufacturing process allows touchscreens to be flexible, curved, 3-D or wearable.

February 1, 2016

Four Ways to Improve Communication at Work

It is possible to build better workplace relationships by communicating clearly and confidently.

February 1, 2016

Market Trends

UV-Curable Ink Applications Increase

Growth in the UV-curable ink market is being spurred by increased use in food and beverage packaging.

February 1, 2016

Market Trends

Convertible Flexible Packaging Demand Increases

Growth areas for flexible packaging include both food and nonfood applications.

February 1, 2016

Transforming the World through Technology

Experts believe these three technologies will have great potential in the next five years.

February 1, 2016

Curing Adhesives: When Less Intensity Is More

More intensive curing lamps can accelerate the production process of light-curing adhesives, but only up to certain limits.

February 1, 2016

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing