Featured on Home Page

Two-component, solvent-free epoxy adhesive material provides high adhesion to metallic substrates while also withstanding high movement or cyclic fatigue.

Read More

Is It Time to Diversify Your Product Line?

To remain agile and create a resilient product portfolio, companies must consider finding new chemistries and materials suppliers.

August 17, 2023

Into the Mix: Design Features that Increase Product Mixing Efficiency

When choosing a mixer, quality and performance are crucial to attain the required product specifications while meeting inevitable changes in customer demand.

August 15, 2023

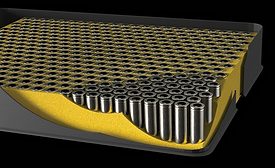

Polyurethane Foam Encapsulant Protects and Lightens EVs

A two-component, ultra-low density, flame-retardant polyurethane foam is designed for potting and encapsulating lithium-ion battery cells in EV battery modules.

August 14, 2023

ASC Sustainability Summit Offers Industry Solutions

The second-annual ASC Sustainability Summit is scheduled for September 18-20 at the Omni Louisville Hotel in Louisville, Kentucky.

August 11, 2023

Advanced UV-Adhesives Help Industry Stick to Future EU Labeling Laws

Advanced cyanoacrylates will enable manufacturers to meet current and future sustainability and ESG reporting needs, and comply with future labeling requirements.

August 9, 2023

Mixing Technologies for the Production of Low- to High-Viscosity Adhesives

A number of factors, primarily viscosity and shear input, are considered when selecting the correct mixing technology for an adhesive formulation.

August 7, 2023

The Benefits of Caprolactone Technology in Reactive Hot Melt Adhesives

As market drivers accelerate the adoption of polyurethane reactive hot melt adhesives away from solvent-borne solutions, the use of polycaprolactone technology in reactive hot melt adhesive applications is examined.

August 3, 2023

2023 Raw Materials and Chemicals Overview

Chemical companies’ attention has shifted from demand issues to more sustainable practices in an effort to address rising production and transportation costs, greater demand to reduce carbon footprint, diminished profitability, and the push to develop more recyclable products.

August 1, 2023

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing