Featured on Home Page

Environmentally friendly cleaning and preventative maintenance can pay dividends in terms of efficient operation and a safer manufacturing environment.

Read More

Tape Talk

Pressure Sensitive Tape Council: Forging a New Path

The Pressure Sensitive Tape Council plans to provide its members with new opportunities to network and continue refining their skills.

April 8, 2021

Advancing Adhesives

Structural Adhesive Pushes Performance Boundaries for Composite Armor Systems

A new high-strength and highly ductile adhesive offers performance benefits in the harshest operating environments.

April 5, 2021

Testing Adhesives: Force Measurement to the Rescue

Recent advancements in force measurement can help adhesives manufacturers keep up with changing customer demands.

April 1, 2021

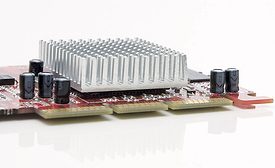

Adhesives for Electronics Assembly

Adhesives provide a strong bond during electronics assembly while protecting components against potential damage.

March 29, 2021

Improving Efficiency and Sustainability in Composites Bonding

A new system comprising a curing oven, regenerative thermal oxidizer (RTO), and secondary and tertiary heat exchangers can help reduce operating costs while ensuring the safe removal of volatile organic compounds during composite bonding processes.

March 24, 2021

Case Study

Optimizing Efficiencies for Hot-Melt Adhesives

A Spain-based tape manufacturer has optimized its production process with the installation of a new static mixer reactor.

March 22, 2021

Exploring Renewable Carbon-Based Raw Materials for Adhesives and Sealants

Producers of adhesives and sealants can reduce their carbon footprints by turning to materials based on renewable carbon sources, but obstacles remain.

March 18, 2021

Ask Dr. Dave

Understanding Two-Component Adhesives

Why do we have to use two-component adhesives and meter/mix equipment in our assembly and repair operations?

March 16, 2021

From the Editor

COVID-19 Prompts A New Digital Age: ASI Launches Dynamic eMagazine Format

Many of the adaptations innovated in the past year due to the necessity of COVID-19 have actually made our lives easier and more efficient—and we aren’t looking back.

March 11, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing