Featured on Home Page

To remain competitive, suppliers must deliver innovations that enable formulators to develop products that satisfy consumer demand.

Read More

Advancing Adhesives

High-Performance Bonding

New adhesives offer manufacturers solutions to reduce weight and gain fuel efficiency.

November 1, 2017

Advancing Adhesives

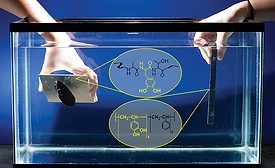

Underwater Bonding

A new “biomimetic” glue can provide high-strength bonding under water.

November 1, 2017

Is Your Company the Next Blockbuster?

Sparking new innovation can help companies succeed.

November 1, 2017

Top 5 News that Sticks

Bostik News Receives Most Reader Interest

Last week, readers were most interested in Bostik’s expansion news.

October 30, 2017

Advancing Adhesives

Solving Engineering Challenges with Functional Coatings

Teflon™ and other functional coatings can solve design problems including excessive wear, sticking, noise, and corrosion.

October 27, 2017

Is Glue the New Fashion Trend?

Fashion designers are entering the runways with something a little different than consumers are used to seeing in clothing lines: stitch-free clothing.

October 25, 2017

Royal Adhesives and Sealants Sale to H.B. Fuller Final

"We are proud of our commitment to innovation and our long-term customer relationships," said Ted Clark, president and CEO of Royal.

October 24, 2017

Top 5 News that Sticks

PPG/Renault-Nissan Partnership Made Top News

Readers were most interested in PPG’s partnership with Renault-Nissan Alliance last week.

October 23, 2017

Case Study

Creating a Better Bond with Laminated Coil

OEMs turn to custom formulators to solve complex adhesion problems with laminated coil and sheet metals.

October 20, 2017

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing